Bigcypresshunter

Sapphire Member

- Joined

- Dec 15, 2004

- Messages

- 27,000

- Reaction score

- 3,340

- Golden Thread

- 0

- Location

- South Florida

- Detector(s) used

- 70's Whites TM Amphibian, HH Pulse, Ace 250

- Primary Interest:

- Beach & Shallow Water Hunting

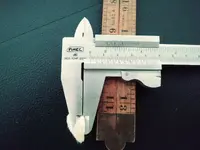

It doesn't seem to have any identification or serial numbers. I was told its a ladies rifle. Its a cool lightweight cap and ball type muzzleloader. I believe it to be authentic. It might be .22 caliber or .25. Check out the hammer and nipple on the bottom. The only marking I see is hand stamped "A.STORY VT."

Any idea what this is? Help needed from the antique gun people. Thanks

pictures loading very slow and having problems they are so big

[/ATTACH]

[/ATTACH]

Any idea what this is? Help needed from the antique gun people. Thanks

pictures loading very slow and having problems they are so big

[/ATTACH]

[/ATTACH]

Last edited:

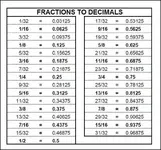

but it looks as if I need a dial caliper for a more accurate reading. (I.D. is inside diameter)

but it looks as if I need a dial caliper for a more accurate reading. (I.D. is inside diameter)