Remember the RIV_ _ that was pointed out earlier by Big Cy? Check this out!

It also became apparent during the 1850's that albumen paper required a certain type of raw paper stock in order to obtain the best results. Experience showed that a thin, smooth paper of exceptionally high quality was necessary for success. The production of such paper was no easy matter; the main difficulties were the prevention of metal flecks in the paper and the need for an abundant supply of mineral-free water. These kinds of impurities proved extremely troublesome both in the paper manufacturing process and also when the paper was coated with highly reactive photographic solutions. The causes of metal flecks in the rawstock were metal buttons left in the rags used to make the paper, and bits of metal breaking off the paper-making machinery itself. Since water purification techniques were not very advanced at that time, only nature could provide a supply of mineral-free water, and such places were rare. The mill of the Blanchet Frères et Kléber Co. in Rives, France, was located in a valley and used water from a nearby mountain lake, fed by "the melting of the alpine snows. Apart from all this was the enormous amount of capital required to construct a paper mill, and the fact that the skill and experience of the staff above all else contributed to a consistently good paper.

Below: 1885 advertisement for albumen paper. Note references to "Rives" and "Saxe" rawstock.

It is no wonder that only two paper mills in the world managed to consistently produce a paper of the necessary quality, and these two mills were able to maintain their monopoly from the 1860's until approximately World War I. They were the above-mentioned Blanchet Frères et Klébler Co. in Rives, France (hence their product was known as the "Rives" paper) and Steinbach and Company, located in Malmedy, Belgium (at that time part of Germany). Steinbach paper was known outside Germany as "Saxe" paper. Both papers were machine-made all-rag papers, sized with a mixture of starch and resin soap. One analysis of Rives photographic rawstock conducted in 1904 showed it to be comprised of 85% linen fiber and 15% cotton fiber.

Have a happy Independence Day

Have a happy Independence Day

as a matter of fact, this might have been the " Black Velvet " syle of that time period. Meaning evrybody including Uncl Joe was doing it. A fad, if you will.........NGE

as a matter of fact, this might have been the " Black Velvet " syle of that time period. Meaning evrybody including Uncl Joe was doing it. A fad, if you will.........NGE

or ideas would be appreciated...any idea is better than no idea!!

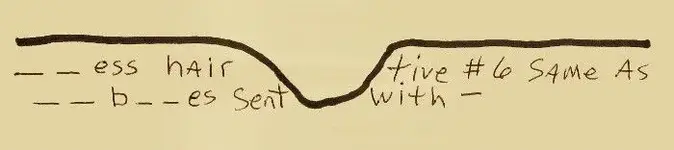

or ideas would be appreciated...any idea is better than no idea!!![Old Photo Close Up Of Stamp After Scraping 001 (900x281)[1].webp](/data/attachments/525/525233-321c2c56b340af7ca7fe88fc904e6931.jpg?hash=awN8acjDLy)