Subdredger

Banned

- Joined

- Nov 14, 2017

- Messages

- 39

- Reaction score

- 48

- Golden Thread

- 0

- Detector(s) used

- Goldbug 2 ,Makro gold racer,custom built Pi,

- Primary Interest:

- All Treasure Hunting

The video above is a alluvial pacific dredge.

It runs a sluice in there with a float on top to try keep it level.

A sluice in a sub is not what you do,no matter how hard you try.

The flow dynamics have not been thought out/volume not thought out ,so throw the back half away.

The pumps on that dredge are 36v 4700gph.Throw them away as well and put on 12v 4700gph pumps and up the voltage.While your there throw the noz away as well.

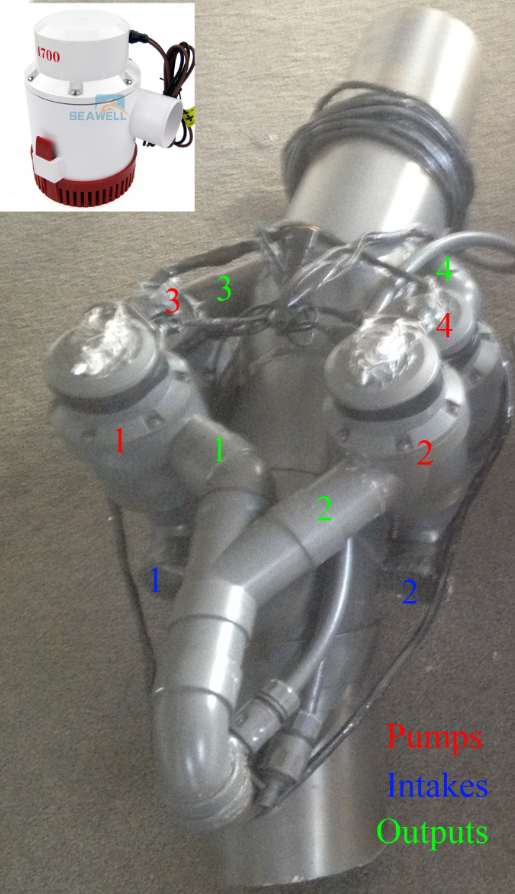

The pumps are made like this.

12v 4700 gph

24v 4700gph

36v 4700gph and

48v 4700gph

So as you can see different voltages same flow.

i chose the 12v 4700gph because as you know it has the biggest gauge wires in it.And we all know what happens when you up the voltage,up the voltage in these wires in the 12v,you get less resistance.

So don't worry about blowing the pump up,it's not going to happen.3 years dredging with this stage one dredge,and all pumps are as new.

So when i put say 24v in ,its a whole different pump ,putting out serious amounts of water.

I have tried to explain how i drop the fines,so i will try again.

Water is so little understood in mainstream anything,the education simply just isn't there for you.

What it comes down to is water holds memory,electrical charge memory,ph memory,when frozen ,crystal memory.

When you put water threw different metal pipes etc it changes the electrical charge,ph etc of the water.

When you put water threw different magnet setups it also changes it.

Your electric pump has magnets in it whats it doing the the water state?

What metal is your sluice box made of.

What is the charge of the water going over your box.

What is the water ph.

All these things come into play with fine gold recovery.This is why i use inert materials in my builds.

Akaline compressed positive water carries your gold.

Acid expanded water will not carry your gold,it drops out.

As far as the electrics go just use the pwm.

I couldn't even start to explain to you how i do it.

Timberdoodle,Theres alot more going on with electrics than what you may be aware of.

Your ac/dc is your north south pole electronics ,what about east west ?You end up back where you started,well documented in Ed Ledskalins work and others.

And in the end it all comes down to how you use the magnets.

Try this ,Get a couple of ferrite ring magnets,get a washer either s/s or galv,put the 2 north faces together with the washer same circumference as the magnets in the middle.,The 2 north faces now stick together,with 2 south poles at the end,watch the magnetism pull strengthen 10 fold.

Apply this to your electrics.

It runs a sluice in there with a float on top to try keep it level.

A sluice in a sub is not what you do,no matter how hard you try.

The flow dynamics have not been thought out/volume not thought out ,so throw the back half away.

The pumps on that dredge are 36v 4700gph.Throw them away as well and put on 12v 4700gph pumps and up the voltage.While your there throw the noz away as well.

The pumps are made like this.

12v 4700 gph

24v 4700gph

36v 4700gph and

48v 4700gph

So as you can see different voltages same flow.

i chose the 12v 4700gph because as you know it has the biggest gauge wires in it.And we all know what happens when you up the voltage,up the voltage in these wires in the 12v,you get less resistance.

So don't worry about blowing the pump up,it's not going to happen.3 years dredging with this stage one dredge,and all pumps are as new.

So when i put say 24v in ,its a whole different pump ,putting out serious amounts of water.

I have tried to explain how i drop the fines,so i will try again.

Water is so little understood in mainstream anything,the education simply just isn't there for you.

What it comes down to is water holds memory,electrical charge memory,ph memory,when frozen ,crystal memory.

When you put water threw different metal pipes etc it changes the electrical charge,ph etc of the water.

When you put water threw different magnet setups it also changes it.

Your electric pump has magnets in it whats it doing the the water state?

What metal is your sluice box made of.

What is the charge of the water going over your box.

What is the water ph.

All these things come into play with fine gold recovery.This is why i use inert materials in my builds.

Akaline compressed positive water carries your gold.

Acid expanded water will not carry your gold,it drops out.

As far as the electrics go just use the pwm.

I couldn't even start to explain to you how i do it.

Timberdoodle,Theres alot more going on with electrics than what you may be aware of.

Your ac/dc is your north south pole electronics ,what about east west ?You end up back where you started,well documented in Ed Ledskalins work and others.

And in the end it all comes down to how you use the magnets.

Try this ,Get a couple of ferrite ring magnets,get a washer either s/s or galv,put the 2 north faces together with the washer same circumference as the magnets in the middle.,The 2 north faces now stick together,with 2 south poles at the end,watch the magnetism pull strengthen 10 fold.

Apply this to your electrics.

Connect with vehicle not running then start it up after a while.

Connect with vehicle not running then start it up after a while.