LeeOregon

Jr. Member

- Joined

- May 4, 2020

- Messages

- 38

- Reaction score

- 37

- Golden Thread

- 0

- Primary Interest:

- All Treasure Hunting

- #41

Thread Owner

It might sound stupid at first, using well pumps in this application. But I did do a little bit of research first. I started here, where Keene engineering put together a paper on dredging basics/troubleshooting/making your own. Its one of the few places that I was able to find actual number on the flows and PSI needed, but here is the critical distinction:

Flows and PSI needed for suction nozzles/ power jets consumption, NOT what the maximum rating of the pumps are.

http://keeneeng.com/pdfFiles/Keene Pumps 2019.pdf

According to them, here is the important part of the paper for those uninterested in following the link :P

2” dredge pump specifications.

P90G pump produces up to 100 GPM and up to 160 foot head.

2”suction nozzle works at 45 GPM at 35 psi.

2” power jet runs at 63 GPM at 30 psi

2.5” dredge pump specifications.

PHP160 pump produces up to 200 GPM and up to 160 foot head.

2.5” suction nozzle works at 78 GPM at 45 psi.

2.5” power jet works at 106 GPM at 40 psi.

3”and 4” dredge pump specifications.

P180 pump produces up to 250 GPM and up to 160 foot head.

-3”and 4” suction nozzle works at 106 GPM at 45 psi

-3” and 4” power jet runs at 180 GPM at 35 psi

Now the performance characteristics of the pumps:

Power jets/ suction nozzles, according to the keene paper, run at 45 psi. Converted to feet of head thats around 104 ft. On the performance curve for the electric pumps at 103 ft-head they should be putting out roughly 23 GPM, so for two pumps 46 gpm.

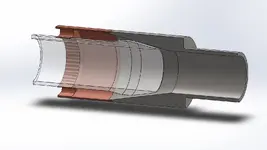

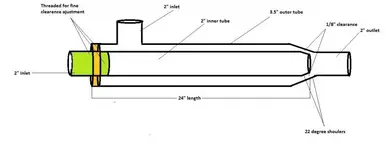

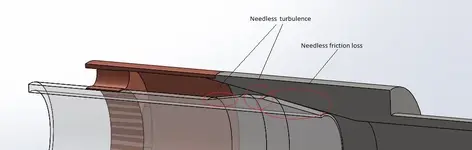

Clearly this is still low for a 3" or even a 2.5" dredge, according to the keene paper. It would be more than enough for 2" though. I just decided to incorporate them into a 3" system first and hope that the increases in efficiency outlined by Phil (Infinity jet, submerged system) would be enough to allow it to function as a slightly under powered 3". And im not sure, but it seems I might have reached that point on the first fireup, with no performance optimization.

Flows and PSI needed for suction nozzles/ power jets consumption, NOT what the maximum rating of the pumps are.

http://keeneeng.com/pdfFiles/Keene Pumps 2019.pdf

According to them, here is the important part of the paper for those uninterested in following the link :P

2” dredge pump specifications.

P90G pump produces up to 100 GPM and up to 160 foot head.

2”suction nozzle works at 45 GPM at 35 psi.

2” power jet runs at 63 GPM at 30 psi

2.5” dredge pump specifications.

PHP160 pump produces up to 200 GPM and up to 160 foot head.

2.5” suction nozzle works at 78 GPM at 45 psi.

2.5” power jet works at 106 GPM at 40 psi.

3”and 4” dredge pump specifications.

P180 pump produces up to 250 GPM and up to 160 foot head.

-3”and 4” suction nozzle works at 106 GPM at 45 psi

-3” and 4” power jet runs at 180 GPM at 35 psi

Now the performance characteristics of the pumps:

Power jets/ suction nozzles, according to the keene paper, run at 45 psi. Converted to feet of head thats around 104 ft. On the performance curve for the electric pumps at 103 ft-head they should be putting out roughly 23 GPM, so for two pumps 46 gpm.

Clearly this is still low for a 3" or even a 2.5" dredge, according to the keene paper. It would be more than enough for 2" though. I just decided to incorporate them into a 3" system first and hope that the increases in efficiency outlined by Phil (Infinity jet, submerged system) would be enough to allow it to function as a slightly under powered 3". And im not sure, but it seems I might have reached that point on the first fireup, with no performance optimization.