AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

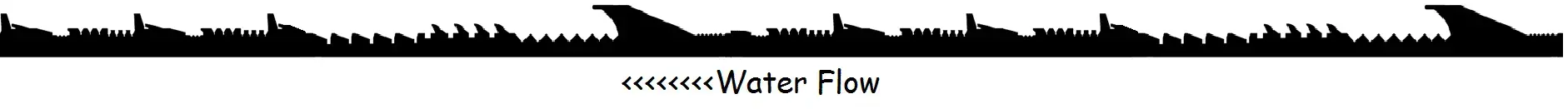

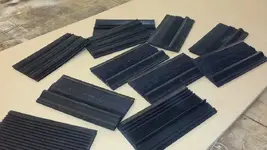

I am about to build a 60" x 12" x 4" X 0.80 Sluice using Gold Hog Mats. The Sluice will sit under my 12" trommel and will be fed by shovel or 5 gallon buckets. Will be using a pump that can deliver nearly 8000 GPH. Please take a look at the image. I had contacted Doc at Gold Hog and he suggested the configuration in the image below. At the end of the Sluice will be a Fluid Bed Gold Trap. The material that we are digging can range from flake gold to 1/4" diameter gold. The trommel will be classifying to 1/2" before dumping into the Sluice. I would like some input from those who are using the Gold Hog Mats, your thoughts, idea's, what your using, how your using the mats, etc. Thank You In Advance

Last edited:

Upvote

0