Crow

Silver Member

- Joined

- Jan 28, 2005

- Messages

- 3,986

- Reaction score

- 11,009

- Golden Thread

- 0

- Location

- In a tax haven some where

- Detector(s) used

- ONES THAT GO BEEP! :-)

- Primary Interest:

- Other

There is nothing incompatible with the copper alloy sheathing and the copper alloy spike. The British began retrofitting all their warships with bronze fasteners by 1786 precisely because of the introduction of copper sheathing. While the possibility of cross contamination can not be ruled out, more than likely you have relics from a British warship that sank sometime after Oct 1793 or 1795.

Can you tell if the small tacks used to fasten the sheathing to the hull are hand made or machine made?

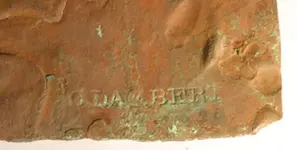

Also, look very closely...there is a chance you might see a mark on a spike...

Gidday Jolly Mon

Good point the sheathing nail square cut or round machine cut nail? As for the sheathing it might pay to look closely and markings on the sheet where it was joined to others.

On your copper sheet you may be able to see where each sheet over lapped? The overlap on the vertical ends “faced aft” to help reduce water being forced into the joint and lifting the sheets. On merchant ships the horizontal joints faced down, while the British Royal Navy applied horizontal joints that faced upwards. So, when the sheeting is found attached to the hull, it not only allows a determination to be made as to the bow and stern but whether the vessel was part of the merchant service.

The arrangement of the tacks (nails) on the sheets varied considerably between shipyards and over time. some are 2-inches apart along each edge (i.e. the overlap) and 4-inches apart on the main part of the sheet and the rows are staggered, which was fairly typical.

Crow

Amazon Forum Fav 👍

Last edited: