AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #21

Thread Owner

MDVGA posted this in the sluicing forum. Thought the ends were rather clever idea. It also shows a slow rotational speed.

So instead of welding a band or 16" bike tire to the outside to use a serpentine belt, use a trailer tire or donut spare from a junk yard

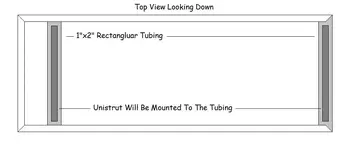

As much as I wanted to use a serpentine belt the added RPM's were to great due to using the 12" cylinder as a pulley so its back to the 14.69" sprocket. I called a buddy of mine who put me in touch with a local machine shop. Turns out this shop can handle up to 36" on their lathe. This shop is going to open the sprocket up so it fits the 12" cylinder tight. Cost $35.00. To me that's well worth the cost. I would have spent more money in blades, grinding wheels, and time in getting the sprocket to be dead center with a dial indicator. Now its slide the sprocket onto the cylinder and TIG weld the smallest welds you can imagine. The plan is to use the solid surface on the sides of the sprocket to have the nylon bushing make contact to keep the cylinder in place. This will eliminate having another 12" ring cut. I may be wrong with this idea but I am going to explore it first.

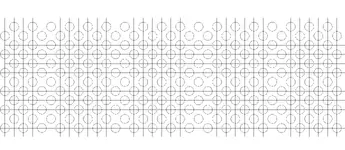

that! LOL thats a bunch o holes. Go down to home depot and get a laborer haha. Good call on building a jig first. Always a good plan even if it takes longer.

that! LOL thats a bunch o holes. Go down to home depot and get a laborer haha. Good call on building a jig first. Always a good plan even if it takes longer.