Justbent

Full Member

- Joined

- Mar 23, 2013

- Messages

- 241

- Reaction score

- 153

- Golden Thread

- 0

- Location

- North Phoenix

- Detector(s) used

- Whites MXT Pro

- Primary Interest:

- Other

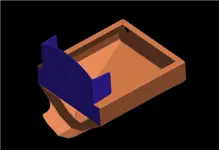

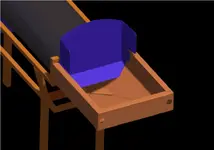

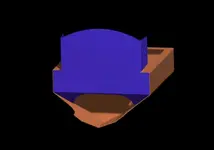

Ya, send me some crude sketches, I'd like to try something like that. With the 3" pump I have the extra water volume and velocity to drive something.I think its a very good possibility. Let me think about it and I will email you. Something that comes to mine is hydraulic water driven motor rotating a half-shaft mounted to your hopper. This half-shaft would have an adjustable counterweight that you could adjust the amount of vibration... You can also control the flow for the amount of vibration.