desertgolddigger

Bronze Member

- Joined

- May 31, 2015

- Messages

- 1,113

- Reaction score

- 2,141

- Golden Thread

- 0

- Location

- Twentynine Palms, California

- Detector(s) used

- Bounty Hunter Time Ranger

- Primary Interest:

- Prospecting

I belong to a local club that owns a claim. This club has had this claim for many years, and acquired it after the old timers had mined it previously, and others after they commercial outfits closed up.

I walked quite a bit of the 160 acre claim, and noted that just about every wash had been worked. Most of the surface nuggets has also been detected by those with gold detectors. In other words, this place has been picked over and over and over.

But I m a stubborn type of person, and I figured, just watching how people ram their puffer and blower drywashers, that some gold was just being blown through them. maybe not much, but some small stuff that never got a chance to settle behind the riffles.

I know many of you would never go to the effort of digging for three to four hours through the tailings in these washes. Again, I'm a bit stubborn, and anyway, I just wanted to have some fun locally, instead of driving 300 miles roundtrip to something that gives a little more for less effort.

I've spent the last three weeks, digging a few times a week along about 30 yards of wash, and have recovered just about a gram of gold. That might not seem like much, but I have only dug up 5 grams, not counting this one gram in almost 20 years out here drywashing in the desert of southern California.

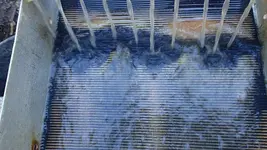

As you would know, things always seem to go wrong. My gas powered blower motor decided it was time for the repair shop, and haven't heard from the shop in two weeks. So I purchased a WORX WG521 corded electric leaf blower to use with my Royal Large drywasher. I'm using a portable generator to provide the power. And it actually is working better than with my old gas powered blower. I have to run the blower on the lowest speed, or I just blow everything through the riffles. Results are very good, as I am getting gold specks so small that I will have to use the Blue bowl in order to recover them.

I'm not only getting a little gold, I'm having some fun, and I am getting a good workout. I've lost 10 pounds since I started. So things are going well.

I'm still digging test holes around the old time hard rock mines in the hope I will find where the gold has drifted downhill below these mines. So far just a couple specks here and there. I figure I just have to move laterally one way or the other before I get something better Of course, I' don't really know if the old timers stripped the hillsides. Even if they have, they apparently aren't as thorough as I am. I hope that I may be lucky and find a larger piece of gold that the old timers, previous placer miners, and detectorists have missed.

Hope everyone is having as much fun as I have been having.

I walked quite a bit of the 160 acre claim, and noted that just about every wash had been worked. Most of the surface nuggets has also been detected by those with gold detectors. In other words, this place has been picked over and over and over.

But I m a stubborn type of person, and I figured, just watching how people ram their puffer and blower drywashers, that some gold was just being blown through them. maybe not much, but some small stuff that never got a chance to settle behind the riffles.

I know many of you would never go to the effort of digging for three to four hours through the tailings in these washes. Again, I'm a bit stubborn, and anyway, I just wanted to have some fun locally, instead of driving 300 miles roundtrip to something that gives a little more for less effort.

I've spent the last three weeks, digging a few times a week along about 30 yards of wash, and have recovered just about a gram of gold. That might not seem like much, but I have only dug up 5 grams, not counting this one gram in almost 20 years out here drywashing in the desert of southern California.

As you would know, things always seem to go wrong. My gas powered blower motor decided it was time for the repair shop, and haven't heard from the shop in two weeks. So I purchased a WORX WG521 corded electric leaf blower to use with my Royal Large drywasher. I'm using a portable generator to provide the power. And it actually is working better than with my old gas powered blower. I have to run the blower on the lowest speed, or I just blow everything through the riffles. Results are very good, as I am getting gold specks so small that I will have to use the Blue bowl in order to recover them.

I'm not only getting a little gold, I'm having some fun, and I am getting a good workout. I've lost 10 pounds since I started. So things are going well.

I'm still digging test holes around the old time hard rock mines in the hope I will find where the gold has drifted downhill below these mines. So far just a couple specks here and there. I figure I just have to move laterally one way or the other before I get something better Of course, I' don't really know if the old timers stripped the hillsides. Even if they have, they apparently aren't as thorough as I am. I hope that I may be lucky and find a larger piece of gold that the old timers, previous placer miners, and detectorists have missed.

Hope everyone is having as much fun as I have been having.

Upvote

49