Goodyguy

Gold Member

- Joined

- Mar 10, 2007

- Messages

- 6,489

- Reaction score

- 6,913

- Golden Thread

- 0

- Location

- Arizona

- Detector(s) used

- Whites TM 808, Whites GMT, Tesoro Lobo Super Traq, Fisher Gold Bug 2, Suction Dredges, Trommels, Gold Vacs, High Bankers, Fluid bed Gold Traps, Rock Crushers, Sluices, Dry Washers, Miller Tables, Rp4

- Primary Interest:

- All Treasure Hunting

- #121

Thread Owner

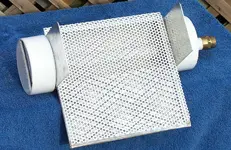

Improvements that were later added to both the "Slick Plate Fluid bed Sluice" and to the high banker "Add a Trap"

Before: "slick plate fluid bed sluice"

After: changed to 11/64" dia. punch plate and connected fluid bed tubes at ends to insure a more even fluidization.

Also removed the plexiglas cover which allows even more fines to enter trap through the punch plate.

Before: "Add a Trap"

After: installed 11/64" dia. punch plate and added second overflow discharge port.

*note diverter baffle located inside to prevent floating gold washout.

Also ..Discharge ports are positioned to be level at a 1 inch to 1 foot rate of overall sluice drop.

Found the punch plate to be more effective for classifying out the debris while still allowing the fines to be trapped.

Go for the gold!

GG~

Before: "slick plate fluid bed sluice"

After: changed to 11/64" dia. punch plate and connected fluid bed tubes at ends to insure a more even fluidization.

Also removed the plexiglas cover which allows even more fines to enter trap through the punch plate.

Before: "Add a Trap"

After: installed 11/64" dia. punch plate and added second overflow discharge port.

*note diverter baffle located inside to prevent floating gold washout.

Also ..Discharge ports are positioned to be level at a 1 inch to 1 foot rate of overall sluice drop.

Found the punch plate to be more effective for classifying out the debris while still allowing the fines to be trapped.

Go for the gold!

GG~

Last edited:

and missed out on a really great piece of gold recovery equipment.

and missed out on a really great piece of gold recovery equipment.