AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

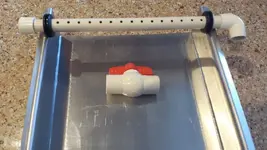

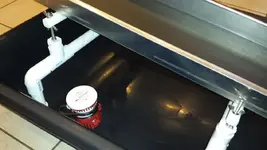

As you can see I have taken a different approach in securing the 1/2" CPVC tubing by using a rubber grommet. Using a Unibit I was able to size the holes slightly small than the OD of the inner grove of the grommet this makes the ID of the grommet slight smaller. This allows the CPVC tube to be very tight within the grommet. The CPVC tubing is sealed and no chance of leaking around the grommets. The 1/8” holes are pointing downward and onto pad within the water box. I installed a top made from a 1/4" cutting board and angled so that the bottom of the front plate will be about 1/2” off of the easy liner for water to escape from under the plate through the Scotch Brite. Some of the photos you will see a ball valve but the finished Miller Table I used a needle and seat valve from Loew's of which will allow for finer adjustment and even out the water flow.

To finish off the Miller Table fine gold recovery system I built a PVC stand with stainless steel all-thread and wing nuts at each corner so I can adjust the level of the table. A 500 GPH 12 volt Attwood was used. I used PVC T fittings that snap over 3/4" PVC pipe so that I can tilt the front or the back of the table to adjust the angle.

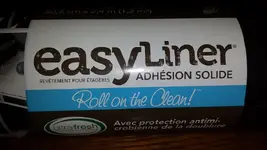

Some of you are having trouble locating Easy Liner here is a link to all the vendors who may carry the product. Granted every store may or may not carry the product. EASY LINER VENDORS

This is what your looking for SOLID Solid Easy Liner® - Black | Duck® Brand EASY LINER

If you cannot find it in your area then buy it online from AMAZON

Duck Brand makes many different colors, textures, widths, and lengths of shelve liners, your looking for Easy Liner Ultra Fresh and currently its made in three colors of White, Tan, or Black. Below is what the texture looks like. The surface has a very slight texture to it, its solid and smooth.

To finish off the Miller Table fine gold recovery system I built a PVC stand with stainless steel all-thread and wing nuts at each corner so I can adjust the level of the table. A 500 GPH 12 volt Attwood was used. I used PVC T fittings that snap over 3/4" PVC pipe so that I can tilt the front or the back of the table to adjust the angle.

Some of you are having trouble locating Easy Liner here is a link to all the vendors who may carry the product. Granted every store may or may not carry the product. EASY LINER VENDORS

This is what your looking for SOLID Solid Easy Liner® - Black | Duck® Brand EASY LINER

If you cannot find it in your area then buy it online from AMAZON

Duck Brand makes many different colors, textures, widths, and lengths of shelve liners, your looking for Easy Liner Ultra Fresh and currently its made in three colors of White, Tan, or Black. Below is what the texture looks like. The surface has a very slight texture to it, its solid and smooth.

Last edited:

Upvote

0

Can't wait for part two! Great job once again AZ!

Can't wait for part two! Great job once again AZ! Oh wait that's old man Hoffman's quote...

Oh wait that's old man Hoffman's quote...