Goodyguy

Gold Member

- Mar 10, 2007

- 6,489

- 6,900

- Detector(s) used

- Whites TM 808, Whites GMT, Tesoro Lobo Super Traq, Fisher Gold Bug 2, Suction Dredges, Trommels, Gold Vacs, High Bankers, Fluid bed Gold Traps, Rock Crushers, Sluices, Dry Washers, Miller Tables, Rp4

- Primary Interest:

- All Treasure Hunting

Good Guy has way more experience than i do when it comes to sluicing. i will say though, i classify down to 1/2 inch for my drop riffle sluice. Im not sure if it is different with expanded metal (or plastic in your case).

My suggestion to classify down to 1/4" had nothing to do with the size of the expanded plastic.

When fine tuning it's just always a good idea to classify down whenever possible. Of course you wouldn't want to miss out on any +1/4" nuggets if they are a real possibility but you also don't want to take a chance on larger gravels causing small pieces of gold to become dislodged from blunt force which could send them back into suspension. Also in order for larger gravels to clear a sluice requires a faster flow that could cause some fine and micro gold loss as well.

Same principal applies when recovering fine gold on a miller table, although a miller table is many times more sensitive to non relative size particles and flow than a sluice with riffles and miners moss.

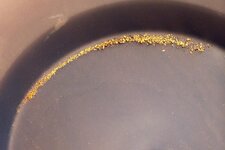

I mostly mine the fine and flour gold found in central Indiana left over from glacial runoff where there is only a remote chance of ever recovering a 1/4" nugget or larger so here every fly poop speck of gold counts and we fine tune our equipment accordingly.

Typical Indiana gold

GG~

Amazon Forum Fav 👍

Last edited:

? Don't you know what fish do in that stuff

? Don't you know what fish do in that stuff