I made this because I did`nt have enough money to buy one, and everything was going good, I kept it under 15 $, until I saw prices on miners moss and v-matting ! Now its almost as expensive as a bought one.. Had to make it all out of wood because I dont got tools for metal. The "expanded metal" is cut out of one of those anti-spin things you put under the wheels of your car if you get stuck in snow

Anyways, I was looking for comments on the miners moss in the end there, do I need to secure it to the bottom somehow? It is easy to pull up , will i get underflow? I put a stopper piece there, as adviced in this thread http://www.treasurenet.com/forums/sluicing/399806-awesome-mod-miners-moss.html It is held down on the sides, but not on the end of it

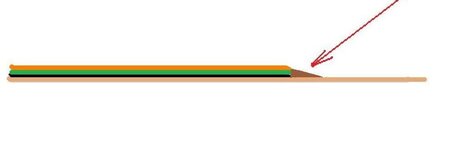

It has v-matting under the moss all the way.

Is the flare too small?

And yes, its pretty heavy! Though it is smaller than it looks on the pictures, just under 6 " wide (working area), and about 45" long. Flare is 14"

Is it way too narrow?

Any comments are appreciated!

Anyways, I was looking for comments on the miners moss in the end there, do I need to secure it to the bottom somehow? It is easy to pull up , will i get underflow? I put a stopper piece there, as adviced in this thread http://www.treasurenet.com/forums/sluicing/399806-awesome-mod-miners-moss.html It is held down on the sides, but not on the end of it

It has v-matting under the moss all the way.

Is the flare too small?

And yes, its pretty heavy! Though it is smaller than it looks on the pictures, just under 6 " wide (working area), and about 45" long. Flare is 14"

Is it way too narrow?

Any comments are appreciated!