DizzyDigger

Gold Member

- Dec 9, 2012

- 6,349

- 12,876

- Detector(s) used

- Nokta FoRs Gold, a Gold Cube, 2 Keene Sluices and Lord only knows how many pans....not to mention a load of other gear my wife still doesn't know about!

- Primary Interest:

- Prospecting

- Thread starter

- #41

Hey DD. How's come you extended Phil's hole towards the river instead of running parallel?

I'd already worked the areas on both sides, so the only way I had to go

was towards the rivers edge. With the water dropping it gave me

several feet of material to work with. As for it being Phils hole or

my hole, no matter really, as Phil and I often dig from the same spots.

We're friends, and he suggested (before I left) that I work that area.

We sure don't get too worked up over $2.00 in gold..lol

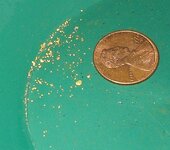

Here's my take, and this was from 49 3gal. buckets of material. Nothing

to write home about, but looks like my usual 1/10th of a gram.

I may be slow, but I'm consistent.

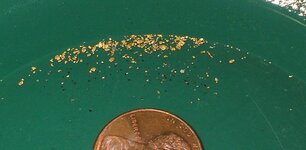

I do love the ease of using the Bazooka, but got to be honest...when

using the Gold Cube I brought home a lot more small gold (<#60 mesh).

I've noticed that when I run Phil's cons for him there is a lot more of the

-30 to +60 material than there is -60 to 100 mesh sized, and it held true

with the material I ran in the Bazooka. This is the opposite of what comes

from the Gold Cube, as I'll have substantially more material in the -60 range.

Could have been the way I set it up, but I've seen Bazookas running enough

times to know how to operate it correctly. For whatever reason though, the

above is what I've experienced.

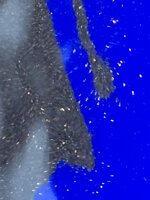

Working on a new classifier for the Gold Cube that will rest on top, and

feed the material directly onto the Gold Cube's slick plate. If it works

as planned, I'll be able to run material just as fast as the Bazooka, but

get the added benefit of the gold catching ability of the Gold Cube.

Some might not understand, but I try to stay out of the river whenever

possible. If I had a bad attack and fell on dry land, the worst I could do was

break a bone, but falling in the water I could easily drown when not knowing

which way is "UP". I can handle breaking a bone, but if I drowned my wife

would kick my ass..lol

Need to do a bit of engineerin' and fabricatin'..no doubt gonna take

a few days, but if it all works right I'll be one happy camper.

Last edited:

.

.

)

) Still, I

Still, I