AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #121

Thread Owner

That's great! I hope you have some great success with your venture. just don't be suprises when that tool guy or Echo develops their own version and stops buying from you.sell all you can now! but good luck!

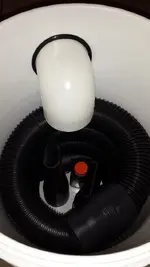

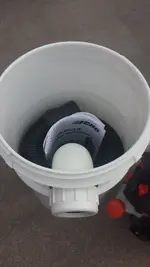

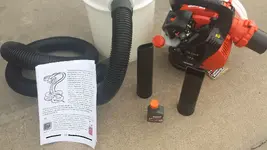

Russ just building them for fun, not out to make money, heck I posted on how to build it so others can build a vac that's better than any other vac currently on the market. In fact I did not charge labor for the one above, just helping a fellow forum member who contacted me. They (Tool Guy or Echo) can have at it, I know it will not be of the quality of the Viper-Vac. The SKIL guy on the other hand may take the idea and run with it, but the vac's have been around for years so let him have at it.

Amazon Forum Fav 👍

Last edited: