Joe,

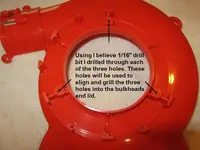

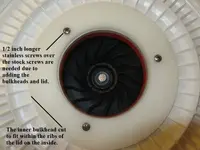

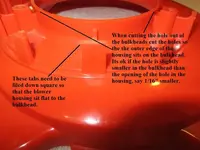

If you were to flip this housing over after its been removed from the blower those three holes from the factory DO NOT penetrate through to the inside of the plastic blower housing, but you need to drill through those holes and penetrate through the blower housing with a slightly smaller drill bit than each of the three holes. This blower housing will be your drilling jig once you center the large fan hole of the blower housing with the large hole in your bulkheads. Once you have these large holes aligned you then can take your drill while drilling from the inside of the blower housing drill through each of the three small holes into the bulkhead. Now you will need to enlarge these three holes in the bulkheads and lid ONLY so that the screws will easily pass through the bulkheads. These screws will attach all the components in this order, finger guard, inside bulkhead, lid, outside bulkhead, then screw into the Echo blower housing. This is why you need new screws that are 1/2" longer. Now once you have the components screwed together look to the inside of the blower housing and make sure that the screws are flush to the plastic blower housing. If they are sticking out you will need to remove each screw one at a time an slightly file or grind the screw down. If you don't the screws will come in contact with the fan blade once you assemble the blower housing with its other half of the blower housing containing the fan and motor.

Hopefully this all makes sense once you have all the components in front of you. I know its sounds like an undertaking but its very simple. Once its assembled you have simply the best Vac on the market, better than anything you can buy cause all the other Vac's (Keene, Jobe, Royal, Vac-Pac, Arizona Gold, Etc.) that I know of have not taken these steps nor use the Echo PB-255 blower, 6 gallon sealed screw on lid, sealed intake fitting, 1/4" bulkheads on either side to secure the blower motor to the lid, and deflector to keep the paydirt from being exhausted and last but not least a Vac that the end user that has built and saved $$$...