Capt Nemo

Bronze Member

I mainly work acrylic and polycarbonate.

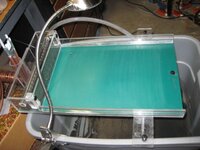

My 10" adjustable dam cutting mat miller table.

I'd like to build another table only with 1/2" sides so I can dado the table and mat down. I also want to modify the dam system so that I can angle the dam a bit more to more easily level the water on the table.

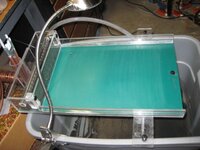

My 10" adjustable dam cutting mat miller table.

I'd like to build another table only with 1/2" sides so I can dado the table and mat down. I also want to modify the dam system so that I can angle the dam a bit more to more easily level the water on the table.