Master-Peter

Jr. Member

Hi folks,

coming from a country with nearly no gold anymore I was bitten by the gold bug some time ago. To start with I must admit I even never had a pan in hand before. I was raised and grew up in the Harz mountains and learned from my parents and grandparents there is no gold in the Harz. So I never gave it a thought or try. Nowadays the internet says (according to old documents) there is some and I'd like to go to the creeks and rivers of my childhood and give it a try. So I had a look for equipment that does the job, is affordable and does nit break the bank or back of a nearly 50 years old guy. It seems the Bazookas are state of the art.

Funny thing is I came across the original Schmidt patents when researching a method to uncover a long lost treasure ship in the phillipines for a friend of mine over there. But the time was not wasted for I'll be there in july knowing that theres gold in that hills...

But back to my thoughts on the Bazookas ...

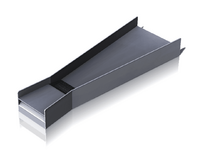

1.) I'm wondering why they go narrower up to the end. For the top part I get the idea, because of rising pressure to get rid of the "waste". But for the fluid bed I'd expect to widen it would help heavies to settle down, because of fluid dynamics - what we all want. When I watch the pictures I cannot get the sense exept manufacturing cost.

2.) Grill clogging .... when the sluice gets narrower all the way down, the grill might as well. That might help clogging. If the grill would widen a bit from beginning it might prevent clogging.

3.) Additional drop down plate ... if the plate at the end of the grill would be bent and directed down into the whirlpool wouldn't that improve recovery by forcing all particles below waterline?

4.) makes it sense to bent the top slick plate some degrees down behind the grill to make even more goodies go down to be processed in the whirl pool?

Sidenote: If we made the whirlpool straight or expanding, a "tray" version could be made to ease cleanout for old men like me and over...

That's all my thoughts at the moment. I tried to make it as clear as a foreigner can do. In case you don't get it, feel free to blame my english.

Thanks for reading and hopefully considering...

Peter

coming from a country with nearly no gold anymore I was bitten by the gold bug some time ago. To start with I must admit I even never had a pan in hand before. I was raised and grew up in the Harz mountains and learned from my parents and grandparents there is no gold in the Harz. So I never gave it a thought or try. Nowadays the internet says (according to old documents) there is some and I'd like to go to the creeks and rivers of my childhood and give it a try. So I had a look for equipment that does the job, is affordable and does nit break the bank or back of a nearly 50 years old guy. It seems the Bazookas are state of the art.

Funny thing is I came across the original Schmidt patents when researching a method to uncover a long lost treasure ship in the phillipines for a friend of mine over there. But the time was not wasted for I'll be there in july knowing that theres gold in that hills...

But back to my thoughts on the Bazookas ...

1.) I'm wondering why they go narrower up to the end. For the top part I get the idea, because of rising pressure to get rid of the "waste". But for the fluid bed I'd expect to widen it would help heavies to settle down, because of fluid dynamics - what we all want. When I watch the pictures I cannot get the sense exept manufacturing cost.

2.) Grill clogging .... when the sluice gets narrower all the way down, the grill might as well. That might help clogging. If the grill would widen a bit from beginning it might prevent clogging.

3.) Additional drop down plate ... if the plate at the end of the grill would be bent and directed down into the whirlpool wouldn't that improve recovery by forcing all particles below waterline?

4.) makes it sense to bent the top slick plate some degrees down behind the grill to make even more goodies go down to be processed in the whirl pool?

Sidenote: If we made the whirlpool straight or expanding, a "tray" version could be made to ease cleanout for old men like me and over...

That's all my thoughts at the moment. I tried to make it as clear as a foreigner can do. In case you don't get it, feel free to blame my english.

Thanks for reading and hopefully considering...

Peter