Master-Peter

Jr. Member

- Thread starter

- #21

... I guess we may have to agree to disagree. ...

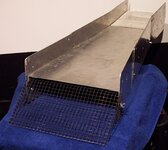

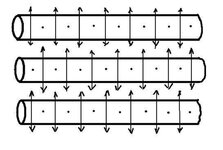

Yep ... but given that opportunity I disagree (for the moment). I got what you think and you might be absolutely right, but I think because the down draft feature does not extend over the grizzly it will not act as a inducer. It should just catch what comes down anyway and lead that on the tubes to be further processed there. I don't expect it to suck down anything for there should already be some kind of backpressure from the tubes.

But that's only me thinking and might proove right or wrong in some distant future.