You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bazooka Gold Company Status?

- Thread starter gldguy1

- Start date

crusty

Jr. Member

Definitely going to have to find a used one before word gets out and prices shoot through the roof! lol

Amazon Forum Fav 👍

Au dave

Sr. Member

- Joined

- Aug 5, 2015

- Messages

- 296

- Reaction score

- 593

- Golden Thread

- 0

- Location

- Eastern Victoria

- Detector(s) used

- Home made drop riffle, 'zook' mini prospector, 'zook' sniper

- Primary Interest:

- Other

Too late ... I checked fleabay Aus last night and they have risen by $A120 since last week .Definitely going to have to find a used one before word gets out and prices shoot through the roof! lol

Sent from my GT-I9305 using Tapatalk

KevinInColorado

Gold Member

- Joined

- Jan 9, 2012

- Messages

- 7,044

- Reaction score

- 11,399

- Golden Thread

- 0

- Location

- Summit County, Colorado

- Detector(s) used

- Minelab Gold Monster 1000, Grizzly Goldtrap Explorer & Motherlode, Gold Cube with trommel or Banker on top, Dream Mat combo sluice, Angus Mackirk Expedition, Gold-n-Sand Xtream Hand pump

- Primary Interest:

- Prospecting

My three are 'mine, all mine'!

Goldwasher

Gold Member

- Joined

- May 26, 2009

- Messages

- 6,084

- Reaction score

- 13,254

- Golden Thread

- 1

- Location

- Sailor Flat, Ca.

- 🥇 Banner finds

- 1

- Detector(s) used

- SDC2300, Gold Bug 2 Burlap, fish oil, .35 gallons of water per minute.

- Primary Interest:

- All Treasure Hunting

I sold the last one I had, and don't expect to own another.

- Joined

- Jan 6, 2014

- Messages

- 14,768

- Reaction score

- 54,981

- Golden Thread

- 0

- Location

- Brookings-Harbor Oregon

- Detector(s) used

- White's prizm IV

Keene A52 with Gold Hog mats

Gold-N-Sand hand dredge

- Primary Interest:

- All Treasure Hunting

I was hoping that there was an assembly line, a CAD. BGT's being hand built? How long does it take to build one?

If you have to start/build an assembly line.... And the patent is expired. Why not just start from scratch?

You need to be able to build enough units so that there is no waiting, and they need to be shipped fast, that's how it works today.

If everyone that wants one....gets one...then what? Are there enough NEW prospectors out there?

If you have to start/build an assembly line.... And the patent is expired. Why not just start from scratch?

You need to be able to build enough units so that there is no waiting, and they need to be shipped fast, that's how it works today.

If everyone that wants one....gets one...then what? Are there enough NEW prospectors out there?

The Aluminum Monster

Hero Member

- Joined

- Mar 18, 2015

- Messages

- 594

- Reaction score

- 776

- Golden Thread

- 0

- Location

- New Bedford, MA

- Detector(s) used

- White's Coinmaster Pro, Tesoro Mojave, Garrett AT Pro, 5x8 DD, 15" NEL Attack, Garrett Pro-pointer, Pro Series 5x9 sand scoop, 30" Royal Compact sluice, 36" Bazooka Gold Trap, Gold Cube.

- Primary Interest:

- All Treasure Hunting

Uggghhhh. I am so sad to hear this. When I got my tax return, I was going to buy a few snipers and send them to my brother-in-law(ish) in Colorado so we had them to use when I would go out and visit him. I'm not hauling mine out there when I visit. ESPECIALLY now when it can't be replaced.

We don't have great gold out here in my area without several hours of travel, but my BGT has been very successful in keeping it if I am on it. I am so saddened by this news.

We don't have great gold out here in my area without several hours of travel, but my BGT has been very successful in keeping it if I am on it. I am so saddened by this news.

Goldwasher

Gold Member

- Joined

- May 26, 2009

- Messages

- 6,084

- Reaction score

- 13,254

- Golden Thread

- 1

- Location

- Sailor Flat, Ca.

- 🥇 Banner finds

- 1

- Detector(s) used

- SDC2300, Gold Bug 2 Burlap, fish oil, .35 gallons of water per minute.

- Primary Interest:

- All Treasure Hunting

nope so what do you do with an assembly line when you get three orders a day?I was hoping that there was an assembly line, a CAD. BGT's being hand built? How long does it take to build one?

If you have to start/build an assembly line.... And the patent is expired. Why not just start from scratch?

You need to be able to build enough units so that there is no waiting, and they need to be shipped fast, that's how it works today.

If everyone that wants one....gets one...then what? Are there enough NEW prospectors out there?

Goldfleks

Sr. Member

- Joined

- Jan 30, 2016

- Messages

- 490

- Reaction score

- 791

- Golden Thread

- 0

- Location

- California

- 🏆 Honorable Mentions:

- 1

- Detector(s) used

- Whites MXT-300, Tesoro Sand Shark 10.5", Bazooka Sniper, Bazooka Prospector

- Primary Interest:

- All Treasure Hunting

I sold the last one I had, and don't expect to own another.

Arrives today, thanks again!

placertogo

Sr. Member

Personally, if the patent matters permit, I would like to see Doc of GoldHog do a manufacture of this sluice using his state of the art technology. The quality would be top notch and the service excellent.

bcfromfl

Full Member

- Joined

- Feb 18, 2016

- Messages

- 249

- Reaction score

- 304

- Golden Thread

- 0

- Location

- Youngstown, FL

- Detector(s) used

- GPX 4500,

Fisher Gold Bug Pro,

Gold Hog stream sluice

- Primary Interest:

- All Treasure Hunting

Personally, if the patent matters permit, I would like to see Doc of GoldHog do a manufacture of this sluice using his state of the art technology. The quality would be top notch and the service excellent.

I agree that Doc could do a bang-up job of re-creating the design, however, after all the reading and watching videos of the Bazooka I've done over time...and despite all the great reviews from users...I'm not convinced it recovers gold better than Doc's stream sluice with Gold Hog mats. At the risk of sounding like a fanboy, a single drop-chamber/fluid bed just doesn't seem like it has the same potential as multiple drop zones like a series of Gold Hog mats has.

One of the main criticisms of the Bazooka I have is that there is no washing/tumbling action like there would be in a more traditional setup. Material dumped into a Bazooka just seems to slide along the header area, and I've actually seen in videos clumps of material going right over the grizzly and out the end. If your material is clean and loose, then no problem, but any clay or stickiness to it is going to be problematic.

I'm sure Doc wouldn't want to sell something at a similar price point to his existing products, that didn't offer the same value. Bazooka has a considerable following, but, at the very least, I see it at odds with the Gold Hog business model. No reason for Doc to cannibalize sales of his already great line-up.

goldog

Hero Member

- Joined

- Sep 25, 2012

- Messages

- 923

- Reaction score

- 987

- Golden Thread

- 0

- Location

- Tujunga, CA

- Detector(s) used

- Bazooka Gold Trap, A-51, Gold Pan

- Primary Interest:

- Prospecting

nope so what do you do with an assembly line when you get three orders a day?

This is what I wondered. Three a day is around 100/mo, 1000/yr. in (very) round numbers. Next question , is man hours. I did some , again, very rough estimates on what may be there.

A $200 prospector I would guess, is $50 materials, 60 labor and let's say 30 in "overhead". Leaving a moderate profit of around thirty dollars. Am I in the neighborhood? If these assumptions are close, someone could make it work. Not get rich but not starve either.

Goldfleks

Sr. Member

- Joined

- Jan 30, 2016

- Messages

- 490

- Reaction score

- 791

- Golden Thread

- 0

- Location

- California

- 🏆 Honorable Mentions:

- 1

- Detector(s) used

- Whites MXT-300, Tesoro Sand Shark 10.5", Bazooka Sniper, Bazooka Prospector

- Primary Interest:

- All Treasure Hunting

I think part of the problem was the product line in itself. There really was no reason to have 3 different models of the same sluice. Miner/Prospector/Sniper/Mini was fine. There was no need for 24" Sniper, 30" Sniper, 36" Sniper. Having such a large amount of product diversity really inhibits your ability to mass produce/stockpile inventory. Not to mention configure your cutting pattern to maximize useable surface area and minimize waste. If someone wants a sniper, just offering the 36" model would have been fine. Everyone would of purchased it. But when you give multiple different models of the same sluice you have people ordering all different sizes of the same sluice. You're losing money when someone purchases a 24" sniper at $145 vs the 36" at 165, when the labor to make them is the same not to mention you're forced to make them on demand because you can't predict if the 24" the 30" or the 36" is going to sell more that moment. So you can't stockpile inventory to meet future demand.

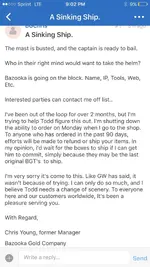

Late X-Mas gift to myself. Can't wait to get her in the river Monday.

Late X-Mas gift to myself. Can't wait to get her in the river Monday.

Attachments

Last edited:

Goodyguy

Gold Member

- Joined

- Mar 10, 2007

- Messages

- 6,489

- Reaction score

- 6,913

- Golden Thread

- 0

- Location

- Arizona

- Detector(s) used

- Whites TM 808, Whites GMT, Tesoro Lobo Super Traq, Fisher Gold Bug 2, Suction Dredges, Trommels, Gold Vacs, High Bankers, Fluid bed Gold Traps, Rock Crushers, Sluices, Dry Washers, Miller Tables, Rp4

- Primary Interest:

- All Treasure Hunting

Anyone know the asking price for the BGT business?

Just curious,

GG~

Just curious,

GG~

arizau

Silver Member

I think part of the problem was the product line in itself. There really was no reason to have 3 different models of the same sluice. Miner/Prospector/Sniper/Mini was fine. There was no need for 24" Sniper, 30" Sniper, 36" Sniper. Having such a large amount of product diversity really inhibits your ability to mass produce/stockpile inventory. Not to mention configure your cutting pattern to maximize useable surface area and minimize waste. If someone wants a sniper, just offering the 36" model would have been fine. Everyone would of purchased it. But when you give multiple different models of the same sluice you have people ordering all different sizes of the same sluice. You're losing money when someone purchases a 24" sniper at $145 vs the 36" at 165, when the labor to make them is the same not to mention you're forced to make them on demand because you can't predict if the 24" the 30" or the 36" is going to sell more that moment. So you can't stockpile inventory to meet future demand.

Late X-Mas gift to myself. Can't wait to get her in the river Monday.

As far as the different lengths of the same model; as a woodworker, I can see where the same tapering jig could be used for all lengths for all models so that seems to me to not be an issue. Other cuts are parallel so no jig required. Some additional waste could be though. Due to a relatively low amount of orders (an average of three per day as stated by an insider in a previous post) labor is an issue since, day to day, it is an unknown as to how many hands are needed to cut, assemble, package and ship the units in a timely manner. If it was not a personal issue then part of the solution could have been to institute no direct sales from the shop. Let retailers order and market what and how many they want and they would have incurred the product inventory expenses. The shop could have committed to not even starting to build additional units until they had a set number of units ordered by retailers. Then they could hire part timers to build that set number of units. Retailers, unlike consumers, are pretty patient when it comes to waiting for a product that is a hot seller.

Just my perspective as a casual observer.

Last edited:

crusty

Jr. Member

Definitely going to have to find a used one before word gets out and prices shoot through the roof! lol

Problem solved! Quick search of local Craigslist and found a 36" prospector AND a Gold Miner wheel with upgraded pump and the 110v converter (Gold Miner Spiral Gold Panning Machine: Spiral Pan Gold Prospecting Machine, Automatic Gold Panning Machine) and a Garrett pinpointer for $400!! Both are damn near brand new! Can't wait to try them out!

rodoconnor

Bronze Member

- Joined

- Mar 4, 2012

- Messages

- 1,419

- Reaction score

- 1,639

- Golden Thread

- 0

- Primary Interest:

- All Treasure Hunting

Meanwhile the oldest manufacturer/builder in the business Keene, keeps plugging along . Maybe Pat and Mark ought to look into this.

utah mason

Hero Member

Anyone know the asking price for the BGT business?

Just curious,

GG~

I was wondering the same thing. I sent them a couple of p.m. inquiring about sales price and if they let the patent expire or if it reached its 20 year exprire date. Haven't heard back. Image that.

Goldwasher

Gold Member

- Joined

- May 26, 2009

- Messages

- 6,084

- Reaction score

- 13,254

- Golden Thread

- 1

- Location

- Sailor Flat, Ca.

- 🥇 Banner finds

- 1

- Detector(s) used

- SDC2300, Gold Bug 2 Burlap, fish oil, .35 gallons of water per minute.

- Primary Interest:

- All Treasure Hunting

I think part of the problem was the product line in itself. There really was no reason to have 3 different models of the same sluice. Miner/Prospector/Sniper/Mini was fine. There was no need for 24" Sniper, 30" Sniper, 36" Sniper. Having such a large amount of product diversity really inhibits your ability to mass produce/stockpile inventory. Not to mention configure your cutting pattern to maximize useable surface area and minimize waste. If someone wants a sniper, just offering the 36" model would have been fine. Everyone would of purchased it. But when you give multiple different models of the same sluice you have people ordering all different sizes of the same sluice. You're losing money when someone purchases a 24" sniper at $145 vs the 36" at 165, when the labor to make them is the same not to mention you're forced to make them on demand because you can't predict if the 24" the 30" or the 36" is going to sell more that moment. So you can't stockpile inventory to meet future demand.

Late X-Mas gift to myself. Can't wait to get her in the river Monday.

Amazing observation skills located HERE ^^^^^^^^^^^^^^

Goldwasher

Gold Member

- Joined

- May 26, 2009

- Messages

- 6,084

- Reaction score

- 13,254

- Golden Thread

- 1

- Location

- Sailor Flat, Ca.

- 🥇 Banner finds

- 1

- Detector(s) used

- SDC2300, Gold Bug 2 Burlap, fish oil, .35 gallons of water per minute.

- Primary Interest:

- All Treasure Hunting

utility patents don't (pre 1995) last 20 years. No one owns the Bazooka patent. Just the name.I was wondering the same thing. I sent them a couple of p.m. inquiring about sales price and if they let the patent expire or if it reached its 20 year exprire date. Haven't heard back. Image that.

Last edited:

Goldwasher

Gold Member

- Joined

- May 26, 2009

- Messages

- 6,084

- Reaction score

- 13,254

- Golden Thread

- 1

- Location

- Sailor Flat, Ca.

- 🥇 Banner finds

- 1

- Detector(s) used

- SDC2300, Gold Bug 2 Burlap, fish oil, .35 gallons of water per minute.

- Primary Interest:

- All Treasure Hunting

it was never a template issue or the ability to "keep up"

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 83

- Views

- 9K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)