Looks good! Happy Drilling...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

12 INCH TROMMEL BUILD

- Thread starter AzViper

- Start date

AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #162

Thread Owner

Wait, if its one long cylindrical tube, are you drilling holes in that?

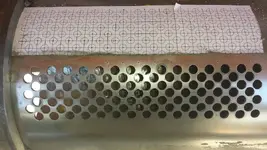

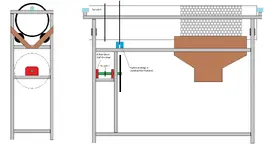

Yes I am drilling the classification are of the cylinder, about 1400 holes. An area about 12 to 15 inches near the end of the cylinder as in this drawing. Everything smaller than 1/2" will drop through the holes and into the sluice. Everthing larger than 1/2" will exit out the end of the cylinder into a wheel barrel dumped and scanned with a metal detector. Click on the images to enlarge...

Last edited:

AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #163

Thread Owner

Looks good! Happy Drilling...

Thanks its not as bad as you would think. Going to drill all the pilot holes first followed by the Unibit to 1/2". Got to get this out of the way soon before shoulder surgery.

Doitlaynstyle

Hero Member

Thanks its not as bad as you would think. Going to drill all the pilot holes first followed by the Unibit to 1/2". Got to get this out of the way soon before shoulder surgery.

So excited to see you working on this again! Was your customer happy with the power chairs?

Doitlaynstyle

Hero Member

How many unibits do you think you will go through? 1400 holes is a lot of holes.

AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #166

Thread Owner

How many unibits do you think you will go through? 1400 holes is a lot of holes.

I don't think I will open all four packages. I have original Unibits from the developer who came up with the idea years ago that still work. He and I worked for the same company before he sold out and made his millions. The key is keeping them cool and oiled during the drilling process much like any drill bit. As for the Poker Table Chairs I have yet to deliver them as they are sitting here at the house, soon though...

GarretDiggingAz

Hero Member

AZ. Glad to see your baby coming around to fulfillment.

They wanted to do my shoulder as well, but it wouldn't help arm, so I opted to not do it. If the pain would've lessened then sure.

They wanted to do my shoulder as well, but it wouldn't help arm, so I opted to not do it. If the pain would've lessened then sure.

AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #168

Thread Owner

AZ. Glad to see your baby coming around to fulfillment.

They wanted to do my shoulder as well, but it wouldn't help arm, so I opted to not do it. If the pain would've lessened then sure.

I just can't deal with the pain anymore not to mention not being able to lift my arm above my head. I am tough and can deal with lots of pain. I once had a 55 gallon barrel of oil roll off the dock and land on my leg after the barrel cart hook popped off sending me and the barrel of the dock. I was able to get up from that accident and walk away but I was 18 at the time. The next day my knee was 4 times the size it should be, no that's not the knee I had knee replacement. Yeah trying to get the trommel completed cause I am looking at surgery sometime after Thanksgiving and before Christmas. I go for an MRI Wednesday.

AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #169

Thread Owner

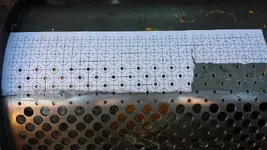

Set out today to get as much done as I can. I was able to drill 105 small pilot holes followed by 105 1/2 inch holes. This represents 12.5 inches in length of classification area. I will continue the drilling the entire circumference of this 12.5 inch wide area until all holes are done. This took me just about 1 hour to do, but the shoulder just could not take any more today. Tomorrow I may try to get out to the gulch but I am not positive on that. LOL

All I know this is going to be a one of a kind cylinder, heavy duty. GolenIrishman had ask if I would be interested in building a second trommel. This will be the only one of its kind from this builder. Sorry Jeff... Now if you ever want a poker table then we will talk, but you have one hell of a wood shop from what you said.

All I know this is going to be a one of a kind cylinder, heavy duty. GolenIrishman had ask if I would be interested in building a second trommel. This will be the only one of its kind from this builder. Sorry Jeff... Now if you ever want a poker table then we will talk, but you have one hell of a wood shop from what you said.

Last edited:

Doitlaynstyle

Hero Member

Set out today to get as much done as I can. I was able to drill 105 small pilot holes followed by 105 1/2 inch holes. This represents 12.5 inches in length of classification area. I will continue the drilling the entire circumference of this 12.5 inch wide area until all holes are done. This took me just about 1 hour to do, but the shoulder just could not take any more today. Tomorrow I may try to get out to the gulch but I am not positive on that. LOL

All I know this is going to be a one of a kind cylinder, heavy duty GolenIrishman had ask if I would be interested in building a second trommel. This will be the only one of its kind from this builder. Sorry Jeff... Now if you ever want a poker table then we will talk, but you have one hell of a wood shop from what you said.

<img src="http://www.treasurenet.com/forums/attachment.php?attachmentid=887611"/>

Only thirteen more hours to go!

AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #171

Thread Owner

Only thirteen more hours to go!

LOL... Thx for those encouraging words my friend. Its all good because at the end I will be able to run some heavy rocks and no more classifying. If you or anyone else would like a copy of this drill temp let me know as I have it in word and as a jpeg.

Doitlaynstyle

Hero Member

Yes please!LOL... Thx for those encouraging words my friend. Its all good because at the end I will be able to run some heavy rocks and no more classifying. If you or anyone else would like a copy of this drill temp let me know as I have it in word and as a jpeg.

kitt

Full Member

- Joined

- Sep 1, 2012

- Messages

- 228

- Reaction score

- 50

- Golden Thread

- 0

- Location

- Brookings Oregon

- Primary Interest:

- All Treasure Hunting

It might be easier to buy 2 burn barrels and weld some punch plate in between. Well would be faster any way, I've drill holes before and it takes some time.

You can also hit up the junk yard for washers and dries and take the drums and weld them.

You can also hit up the junk yard for washers and dries and take the drums and weld them.

AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #174

Thread Owner

It might be easier to buy 2 burn barrels and weld some punch plate in between. Well would be faster any way, I've drill holes before and it takes some time.

You can also hit up the junk yard for washers and dries and take the drums and weld them.

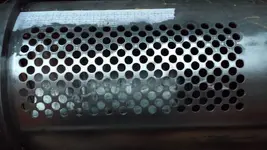

Kitt there is a reason I am building it this way. The cylinder is made of 1/8" plate. It would cost a small fortune to have this cylinder punched out to my spec's. I wanted a very small area reserved for classifications as anything larger is not needed. Most commercial made trommels that are on this scale as in size are using expanded metal and you not going to get 1/8" thick expanded metal with 1/2" openings. Then its welding three sections together, the front, center, the end. I wanted a cylinder strong and could hold up year after year. Last but not least I wanted to build it to my spec's and have my ideas. Sure I could have bought a ready made cylinder from someone out in CA but it would have been made of 16 gauge three section cylinder. This is 11 gauge solid cylinder.

I have thought of the tall 12" propane cylinders tanks that have never had any gas in them. I also had a buddy of mine that works with Ferguson Plumbing Supply try to locate me a 12" thin wall pipe and could not find it. If I had to do it all over again I would still be searching for that pipe. The shop I used here in Tucson is a great shop and the guy I dealt with did not understand the task that was needed to produce a nearly round cylinder. He handed the job over to a greenhorn who had never rolled a steel plate. When a steel plate is rolled the first 3 inches on either end should be pre-rolled to get the curve started. Once both ends are done then place the sheet back into the roller and roll the steel plate and continue to roll the plate until the cylinder is round.

AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #175

Thread Owner

I got some more holes drilled, Still using the same 1/8" bit and Unibit with 195 holes drilled. The Unibit has seen many other holes drilled. I decided not to use any oil and just push the bit through the metal. The Unibit has gotten extremely hot and has turned blue but its like the heat has harden the bit even more. Going to see how many holes I can get drilled with the one bit. Its still cutting like a new bit though.

Last edited:

SLNugget

Sr. Member

- Joined

- Sep 25, 2013

- Messages

- 262

- Reaction score

- 233

- Golden Thread

- 0

- Location

- Morristown, AZ

- Detector(s) used

- Gold Bug Pro

- Primary Interest:

- Prospecting

I have an original Unibit from the 70's that's still going strong after building, maintaining and racing a lot of racecars. Perfect tool for that sort of thing. Hard to kill one. Nice work as usual, Keith !

Doitlaynstyle

Hero Member

Amazing work there! That pattern looks great and will look great on my build too. Thanks for the updates and inspiration. I finally pulled together the cash today for the cylinder on mine. And should have a little extra for some steel. I'm still having a hard time figuring out the main gear but once I do look out lol

AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #178

Thread Owner

I have an original Unibit from the 70's that's still going strong after building, maintaining and racing a lot of racecars. Perfect tool for that sort of thing. Hard to kill one. Nice work as usual, Keith !

Thanks Stan... What kind of racing are you involved in? This is my brother and I at the BF Goodrich S.C.O.R.E Off-Road World Championships in 1979 where we finished 2nd. I am seated in the co-driver seat. We race all the big events for a number of years including Baja 500, Baja 1000, Mint 400, Parker 400, Etc. This was an unlimited Class 2 car, but we also had an unlimited Class 5 car as well. The photo is from the old Riverside Raceway in California. Back then it was totally amazing start to the race. The cars were lined up much like Motocross is. We had a good 3/8 of a mile straightway where all the cars were funneled into the first hard left turn on asphalt in front of the main grandstands. Speeds of 130 MPH heading into that first turn was insane as all cars had to make the first lap or the race had to start all over. This day we had 4 restarts before all cars made the first lap. So many cars were flipping because being open wheel the wheels would get tangled up. This is where my welding skills grew from as we built all our own cars. The center photo gives you an idea of what the old track use to look like look towards the grandstands.

Last edited:

AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

- #179

Thread Owner

Amazing work there! That pattern looks great and will look great on my build too. Thanks for the updates and inspiration. I finally pulled together the cash today for the cylinder on mine. And should have a little extra for some steel. I'm still having a hard time figuring out the main gear but once I do look out lol

Layn,

Yeah it is a good pattern that's not going to let gold slip by even with the 12" classification area, What size cylinder or pipe did you get? If you can get a gear reduction will be better. I have slowed my trommel down to about 27 RPM's although I like it to be slightly slower but I have yet to put material and water through the trommel. I can slow it down further by going to a larger belt pulley of 14" or 16".

Last edited:

jcazgoldchaser

Hero Member

- Joined

- May 8, 2012

- Messages

- 899

- Reaction score

- 515

- Golden Thread

- 0

- Primary Interest:

- All Treasure Hunting

Outstanding! Looks waterjetted.I got some more holes drilled, Still using the same 1/8" bit and Unibit with 195 holes drilled. The Unibit has seen many other holes drilled. I decided not to use any oil and just push the bit through the metal. The Unibit has gotten extremely hot and has turned blue but its like the heat has harden the bit even more. Going to see how many holes I can get drilled with the one bit. Its still cutting like a new bit though.

Are you getting any burr on the inside?

How many holes can you drill before you have to run around the house screaming?

Similar threads

- Replies

- 6

- Views

- 650

- Suggestion

- Replies

- 12

- Views

- 980

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)