I'm going to tinker with the two 5-hp Briggs that came on the tillers. If I cant get them to run reliably I will go the same route as you AZ and purchase the predator motor from harbor freight. I already have one on my pump and even at full throttle I get 2.5 hrs of run time on a gallon. Starts first pull every time. Last weekend I had to till my garden spot to get it ready for next season and that was what sparked the search for tillers. I rented the one I used for $45 dollars for "2" hours. If you go in an hour before they close and you return it within an hour of opening the next day you only get charged 2 hours and you can use it overnight. The tiller already has the entire engagement/disengagement system and motor mount built right onto the dual 1/4 X 2 angle frame and All it looks Like I will have to do is cut the "tines" off far enough away from the gearbox to be able to mount the sprocket on there and mount the thing to the trommel frame. Also going to have to figure out how I want to mount the sprocket.

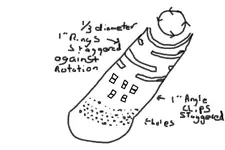

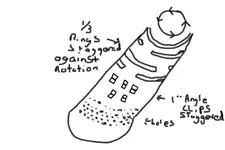

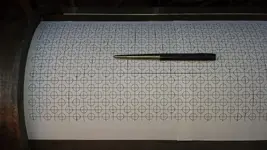

I found a 60" chunk of 12 ga tube with a 16" diameter at the local steel yard for $120 that I will be picking up fairly soon. Probably going to be plasma arcing all of my 1/2 inch holes. First I will layout all of the holes and centerpunch the locations in case I want to drill instead and then I am thinking it would take around a day with the plaz to burn all the holes with a circle burner. I will be using a removable grizzly directly under the holes in case I want to classify smaller. According to my math a 12" wide swath of holes will be more than sufficient to allow all of the water/slurry to flow out into the sluice. If I have to add more later I can. I also am going to have to buy a trailer to haul this thing on as this will be drastically increasing the amount of equipment I will be taking with me each time I go out. I am attaching a crude drawing that kinda gives you an idea of what I am going to do on the inside of the trommel to help bust up clay and clods.

View attachment 881434