AzViper

Bronze Member

- Sep 30, 2012

- 2,038

- 2,251

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

This thread has gotten very large and you will need to work through all the pages to view all the images of this build. The project started out to be completed quickly but family and medical issues popped up during the course of the build. Each of the 1434 holes were drilled by hand. This allowed for a much stronger cylinder over using expanded metal. The classifying area is much smaller than others used. More of the cylinder was reserved for breaking up and cleaning before heading to the classifier. Here are updated photos of the finished trommel.

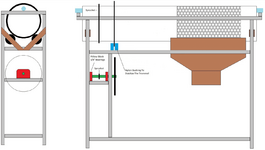

I will begin my trommel build soon. Been gathering ideas and have come up with a plan. I am a believer that the classification area does not need to be all that large. The idea is to wash and tumble the rocks/dirt prior to the rock/dirt arriving at the classification area. Furthermore The spray bar will be mounted inside the cylinder so that the rocks get washed properly while 3/4" angle iron welded in the solid section of the cylinder as shown in the diagram below. Using this method will allow the rocks to fall away while still agitating the rocks. There will be no issues with rocks climbing the walls of the cylinder due to centrifugal force while maintaining a cylinder RPM between 18 and 30 RPM's due to the RPM of the engine. My gear reduction will be, Engine 2" pulley to a 12" pulley, then a 1.625" sprocket to a 14.69" sprocket. At 1000 engine RPM the cylinder will rotate 18.5 RPM's. At 1500 engine RPM's the cylinder will rotate at 27.5 RPM's.

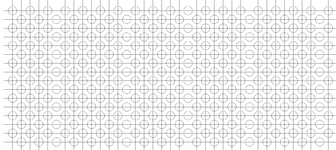

The cylinder will have 1/2" holes drilled in this configuration. 3/4 inch angle iron will be welded to the inside..

I picked up the rolled 1/8" cylinder. Will use the drill guide to punch mark where the holes will need to be drilled. The solid rolled steel cylinder will be strong due to its solid design and not made from 3 separate pieces of metal. After reading the reviews on the Predator 6.5 HP engine in the go kart forums it was a no brainer not to try the motor, if it does not work out then a Honda will be put in its place. Picked it up for $79.00 new.

The 14" sprocket, 2" sprocket, 2" pulley, 12" pulley, 3/4" flange bearings, roller blade wheels are on the way. Everything else I can pick up locally. I have all the square tubing in the shop. Hopefully I can begin soon. I have a poker table to finish up for a client this next week.

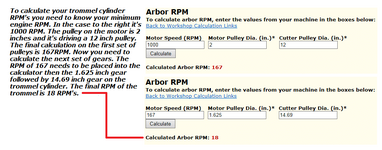

Here is a nice RPM / Pulley Calculator. Very easy to use. Just enter data into three of the four boxes to arrive either pulley size or RPM whatever you choose. If you need to use a secondary step-down reduction of RPM's make sure you use the RPM from your first calculation to get your final RPM. You can also download the calculators so it runs from your computer. EXAMPLE: In this example I knew my engine RPM, sprocket size, and pulley size. The calculator calculated my final cylinder RPM.

UPDATE: I added a new calculator for RPM's the old calculator was removed by the designer.

RPM CALCULATOR

I will begin my trommel build soon. Been gathering ideas and have come up with a plan. I am a believer that the classification area does not need to be all that large. The idea is to wash and tumble the rocks/dirt prior to the rock/dirt arriving at the classification area. Furthermore The spray bar will be mounted inside the cylinder so that the rocks get washed properly while 3/4" angle iron welded in the solid section of the cylinder as shown in the diagram below. Using this method will allow the rocks to fall away while still agitating the rocks. There will be no issues with rocks climbing the walls of the cylinder due to centrifugal force while maintaining a cylinder RPM between 18 and 30 RPM's due to the RPM of the engine. My gear reduction will be, Engine 2" pulley to a 12" pulley, then a 1.625" sprocket to a 14.69" sprocket. At 1000 engine RPM the cylinder will rotate 18.5 RPM's. At 1500 engine RPM's the cylinder will rotate at 27.5 RPM's.

The cylinder will have 1/2" holes drilled in this configuration. 3/4 inch angle iron will be welded to the inside..

I picked up the rolled 1/8" cylinder. Will use the drill guide to punch mark where the holes will need to be drilled. The solid rolled steel cylinder will be strong due to its solid design and not made from 3 separate pieces of metal. After reading the reviews on the Predator 6.5 HP engine in the go kart forums it was a no brainer not to try the motor, if it does not work out then a Honda will be put in its place. Picked it up for $79.00 new.

The 14" sprocket, 2" sprocket, 2" pulley, 12" pulley, 3/4" flange bearings, roller blade wheels are on the way. Everything else I can pick up locally. I have all the square tubing in the shop. Hopefully I can begin soon. I have a poker table to finish up for a client this next week.

Here is a nice RPM / Pulley Calculator. Very easy to use. Just enter data into three of the four boxes to arrive either pulley size or RPM whatever you choose. If you need to use a secondary step-down reduction of RPM's make sure you use the RPM from your first calculation to get your final RPM. You can also download the calculators so it runs from your computer. EXAMPLE: In this example I knew my engine RPM, sprocket size, and pulley size. The calculator calculated my final cylinder RPM.

UPDATE: I added a new calculator for RPM's the old calculator was removed by the designer.

RPM CALCULATOR

Last edited: