Note: In general, metals with high electrical conductivity also have high thermal conductivity

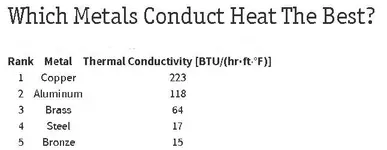

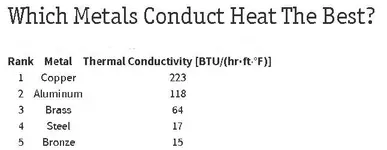

Fair enough,..... look at this chart of the best thermally conductive metals.

Silver – Consequently, silver in terms of conductivity does not take 2nd place. As a result, silver is by far the most conductive metal on Earth. This is because silver only has one valence electron. In addition, this single electron is free to move around with little resistance. As a result, metals like silver and copper are a few of the metals with this particular characteristic. That is why they are great electric and thermal conductors.

Copper – In conclusion, copper like silver, only has one valence electron which makes this metal very conductive. Therefore, one of the more popular commercial applications is the coating of high-end cookware and kitchen appliances.

Gold – Overall, the list is limited and that is a primary reason (other than its rarity) why this material is so expensive. In addition, the combination of gold’s resistance to corrosion and its conductivity make this metal an extremely valuable resource used in large amount of industrial industries.

Aluminum – Overall, is an excellent metal conductor.

This feature, in addition to its low density and

high resistance to corrosion, makes this metal perfect for the aeronautic and communication (transmissions) industries.

Zinc/Brass – Although these metals are much less conductive than their four counterparts. These metals are often less expensive and economical replacements when applicable.

Aluminum, high resistance to corrosion?

Sorry, that is something we have all seen as untrue.

It oxides up, (that white powdery corrosion), if left to the elements.

That is why it's, anodized, plated, powder coated, etc.

I have worked in the FAA aircraft part repair business since the 80's.

"The number 1 cause for losing an aluminum part, "

Corrosion"

And these are parts that are most often surrounded by, and immersed in

hydraulic oil. You would think they would be fine,....

It just takes some water, even condensation, and the parts are pitted.

Often the pitting is deep enough that they can not be local blended out.

A part that can still fulfill the, Form, Fit, and Function,.... get scraped out.

Again, just because you read it on the internet, does not make it true.

You want proof?

"How many hundreds of pictures would you like to see"

In my line of work, it's something seen "Every Day".