BioProfessor

Silver Member

- Joined

- Apr 6, 2007

- Messages

- 2,917

- Reaction score

- 84

- Golden Thread

- 0

- Location

- Mankato, MN

- Detector(s) used

- Minelab e-Trac, White E-Series DFX

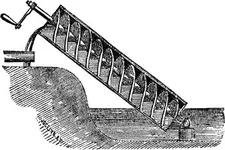

Found this with my rock detector. Tripped over it and dang near speared myself with my MD. Anyway, I haven't a clue what it might be or do (I seem to be saying that a lot lately.  )

)

It is made of clay but is crudely fired. Not fired in a modern or really hot kiln where you get the "ring" when you hit. It just gives a dull "thud" so it's not a modern manufactured piece as far as I can tell.

The outside is just scratched to make the groves. Doesn't look like a very sophisticated process was used.

This piece is 6.50" tall and 6.25" in diameter.

The inside looks like an auger with the center missing. It is very smooth and seemingly precise.

Any reason that a relatively long time ago somebody would make a clay pipe that would make water or air spin around as it passed through (or anything for that matter)?

Thanks,

Daryl

)

)It is made of clay but is crudely fired. Not fired in a modern or really hot kiln where you get the "ring" when you hit. It just gives a dull "thud" so it's not a modern manufactured piece as far as I can tell.

The outside is just scratched to make the groves. Doesn't look like a very sophisticated process was used.

This piece is 6.50" tall and 6.25" in diameter.

The inside looks like an auger with the center missing. It is very smooth and seemingly precise.

Any reason that a relatively long time ago somebody would make a clay pipe that would make water or air spin around as it passed through (or anything for that matter)?

Thanks,

Daryl

not to improve draw, to improve heat tranfer, probably still not right, but a different principle for a different purpose

not to improve draw, to improve heat tranfer, probably still not right, but a different principle for a different purpose  jim

jim