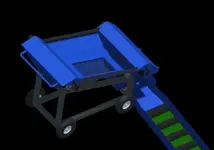

You know, I gotta tell you this. My brother in law and I built my sluice based on pictures of a similar design I wanted. It was 3 months longer in the build and a real budget buster, coming in at twice the cost...mostly due to me. $150 was actually $300+. Anyways, yesterday I ran all of my cons from 2013...found a flake or two on top...haven't panned what's left yet...but I'll tell you this...there is NOTHING like a dialed in sluice of your doing. Great job! Oh yeah, I almost forgot...when I posted my results here, I did the same thing you did...watched the video. And guess what? The sluice TELLS you what to do. I thought I would tell it what to do...