Bonaro

Hero Member

- Aug 9, 2004

- 977

- 2,213

- Detector(s) used

- Minelab Xterra 70, Minelab SD 2200d, 2.5", 3", 4"and several Keene 5" production dredges, Knelson Centrifuge, Gold screw automatic panner

- Primary Interest:

- Prospecting

I have a Keene 5" triple sluice dredge and I have never been able to tune it the way I want it to run. When I do a clean up, if I just shut down and open the sluice, the under riffles will be overloaded every time, no matter how I change the angles or damper opening. I know this is causing me to lose gold. I have fiddles with damper settings and sluice angles and nothing really helps.

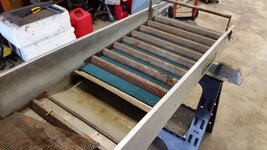

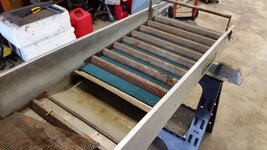

I think I have worked out a solution, I need more water flow in the undersluice. The way it's constructed, only 1/2" of water is allowed over the riffles in the OEM design. I bought some 1/2" x 1/8" steel strap and welded it on edge to the existing rails.

Don't laugh at my welding...my helmet has a goofy photo sensor and when I pull the trigger there is a long full second delay before the lens darkens and I get flashed really good, every time...result is I am welding pretty much blind. With this extra spacing I will now have about a full 1" of water over the riffles.

Raising the damper above the lower riffles also caused the upper riffles to no longer fit. The eash fis was to simply drill new holes and remount it a little higher. However the square holes in the handle would no longer work with the latches. I didnt want to try and cut a square hole so I tacked on a couple small metal tabls and moved the riffles forward an inch.

I now have a really good gap under there and it will flow a LOT more water. Testing to occur this summer, I will let you know.

I think I have worked out a solution, I need more water flow in the undersluice. The way it's constructed, only 1/2" of water is allowed over the riffles in the OEM design. I bought some 1/2" x 1/8" steel strap and welded it on edge to the existing rails.

Don't laugh at my welding...my helmet has a goofy photo sensor and when I pull the trigger there is a long full second delay before the lens darkens and I get flashed really good, every time...result is I am welding pretty much blind. With this extra spacing I will now have about a full 1" of water over the riffles.

Raising the damper above the lower riffles also caused the upper riffles to no longer fit. The eash fis was to simply drill new holes and remount it a little higher. However the square holes in the handle would no longer work with the latches. I didnt want to try and cut a square hole so I tacked on a couple small metal tabls and moved the riffles forward an inch.

I now have a really good gap under there and it will flow a LOT more water. Testing to occur this summer, I will let you know.

Upvote

0