You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Ultimate Home-Built Thread

- Thread starter Caminochaos

- Start date

My Three Stage Classifier for the Gold Cube and my Miller table.

http://s1220.photobucket.com/albums/dd453/tarsus1/

http://s1220.photobucket.com/albums/dd453/tarsus1/

Amazon Forum Fav 👍

Gold_Striker

Full Member

have you ever heard of this ? Bernoulli's_principle Fluid Dynamics VII: The Venturi Effect

A device that uses the rivers own natural flow to act as a means of producing suction.

A device that uses the rivers own natural flow to act as a means of producing suction.

russau

Gold Member

- Joined

- May 29, 2005

- Messages

- 7,680

- Reaction score

- 7,378

- Golden Thread

- 0

- Location

- St. Louis, missouri

Gravel Hog thats a mighty familiar picture of that winch!! your name isnt John by any small chance is it?

Gravel Hog

Sr. Member

- Joined

- Dec 11, 2010

- Messages

- 426

- Reaction score

- 64

- Golden Thread

- 0

- Location

- N. Cal - Born & Raised

- Primary Interest:

- Prospecting

russau said:Gravel Hog thats a mighty familiar picture of that winch!! your name isnt John by any small chance is it?

Might very well be there, Russ.

Hoser, figured all that along time ago.

Gold_Striker

Full Member

Well if I'm ever into a river I just know there has to be a way to go in without having a gas powered machine. Gold cube thanks!

Well if I'm ever into a river I just know there has to be a way to go in without having a gas powered machine. Gold cube thanks!  hmmm.. googling...

hmmm.. googling...Gramps43

Full Member

- Joined

- Feb 27, 2011

- Messages

- 207

- Reaction score

- 27

- Golden Thread

- 0

- Location

- Tillamook, OR

- Detector(s) used

- White's 4900/D Pro Plus

- Primary Interest:

- Prospecting

My version fo a super sucker or as call it my Maxi Hoover. It's made of 3" ABS, the piece of pipe below the hub is a reservior and handy place to attach a foot plate. The input hose has a 5' piece of ½" hi-press. CPVC pipe to give it a long reach.

Gramps

Gramps

Attachments

TheHarleyMan2

Bronze Member

- Joined

- Feb 27, 2008

- Messages

- 1,594

- Reaction score

- 465

- Golden Thread

- 0

- Location

- Never Know I May Live Next To You!

- Detector(s) used

- GTI 2500/Bounty Hunter

Minelab Equinox 800

- Primary Interest:

- All Treasure Hunting

HEY GRAMPS!!!!!!!!!!!! That is JUST what I NEED!!!!! What did you use for the base and the pipe going into the PVC T?

I am going to make one. I searched the internet for good PVC Check Valves and I am not sure which ones to get. I talked with some guy's out at the RRGPAA, (Round Rock GPAA), and they had made one using check valves, (1 1/2"), from Home Depot and they said they get clogged up and don't work very well, being the ones at Home Depot are cheepos.

The area around the Llano River is mostly small granite sand and rock. Any suggestions on what type of check vavle that won't get sand wedged in it to make it not work right?

I am going to make one. I searched the internet for good PVC Check Valves and I am not sure which ones to get. I talked with some guy's out at the RRGPAA, (Round Rock GPAA), and they had made one using check valves, (1 1/2"), from Home Depot and they said they get clogged up and don't work very well, being the ones at Home Depot are cheepos.

The area around the Llano River is mostly small granite sand and rock. Any suggestions on what type of check vavle that won't get sand wedged in it to make it not work right?

russau

Gold Member

- Joined

- May 29, 2005

- Messages

- 7,680

- Reaction score

- 7,378

- Golden Thread

- 0

- Location

- St. Louis, missouri

make your own check valves using rubber test caps that are clamped onto the ends of PVC pipe for /leakpressure testing. all you have todo is slice part of the rubber lip to form the check valve and leave a little of it for its hindge.ofcourse youll need to use a slightly larger PVC pipe around that area. but its cheap and it works!

Heres a little concentrator I made. All aluminum with ripple matting glued down to it, machined the "spillway" on the mill to ensure even flow accross the matting, this thing is tough as nails too, 1/8th aluminum, should be able to park your car on it no problem!!

Soon I'll be making a sluice and I want to incorporate variable widths for either river sluicing, dredging, or highbanking..

Soon I'll be making a sluice and I want to incorporate variable widths for either river sluicing, dredging, or highbanking..

russau

Gold Member

- Joined

- May 29, 2005

- Messages

- 7,680

- Reaction score

- 7,378

- Golden Thread

- 0

- Location

- St. Louis, missouri

looks like you have lots of time on your hands! haha nice looking !!!

TheHarleyMan2

Bronze Member

- Joined

- Feb 27, 2008

- Messages

- 1,594

- Reaction score

- 465

- Golden Thread

- 0

- Location

- Never Know I May Live Next To You!

- Detector(s) used

- GTI 2500/Bounty Hunter

Minelab Equinox 800

- Primary Interest:

- All Treasure Hunting

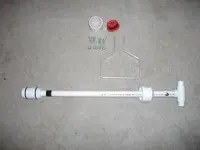

Well after looking at Gold N Sand's Hand Suction Dredge pump I decided to make my own and boy does it work!!!!

I am going to make a video this weekend with me using it at the Round Rock GPAA outing this weekend and will post the video when I get back.

Here is the list of what I used;

(1) 1 1/4" Sump Pump Hose....1 Roll was cheaper at $9.95 per 26ft

(2) 1 1/4" Sump Pump Check Valves......Ace Hardware......$7.00 each

(1) 2" X 2ft PVC pipe

(1) 3/4" X 6ft PVC pipe......used 2ft

(1) 3/4" PVC T........for the handle

(2) 3/4" X 1 1/2".....for the handle

(1) 2" X 2" X 1 1/2" X 1 1/2" 4 way PVC joint

(1) 2" x 3" PVC pipe.......for bottom of 4 way joint

(1) 2" Test plug..............for bottom of 4 way joint

(1) 3/4" X 1/8" X 36" aluminum flat bar.....for foot stirrup

(1) 2" cap...........drill out a center hole slightly bigger than 3/4" to let the pump shaft slide through the cap

(1) 1 1/4" PVC collar

(1) 1 1/4" PVC plug

(1) 1 1/4" X 3/4" adapter

(2) 1 1/2" slip collars

(2) 1 1/2" X 1 1/2" PVC pipe

(4) 5/16 X 3/4' bolts

(4) 5/16 nylon lock nuts

(2) 2" X 1/8" O-rings

For the bucket;

(1) 5 gallon bucket, w/lid

(1) 1 1/4" threaded hose collar.....comes with sump pump hose kit

(1) 1 1/4" threaded female collar

Using a 1 1/4" hole saw drill out a hole in the center of the lid. Insert the hose collar and on the inside of the bucket lid screw the threaded female collar on the hose collar/fitting.

I drilled (6) 3/4" holes around the lid so water can get out of the bucket.

I pretty much glued the pipe together with the 4 way and the check valves. I left the cap loose and ONLY hand pushed it down on the pipe so I can be able to remove the handle and piston to lube or change out the o-rings.

I filed groves in the piston collar and test fit little by little until the piston slid just easy enough to work and still seal. Get some silicome spray lubricant, (NOT the oil base kind), and spray the o-rings so the piston and the o-rings slide up and down in the cylinder easily. Be careful about filing too much down or the o-ring won't seal the cylinder. I also drilled a 3/8 hole into one side of the handle/piston shaft so air can escape the cylinder while pulling the handle up. The black band on the handle shaft is not tape. I painted a black band on it so I know when I am pulling the handle up I have the piston up at the top of the cylinder cap so I won't pop the cap off.

I also just inserted the 2" test plug and tightened it down so I can remove it to clean out the pump and check to see if any gold has been lodged in anywhere.

I bent the aluminum flat bar to make a stirrup to put my foot in while I use one hand to pump and the other to use my suction wand.

I am going to make a video this weekend with me using it at the Round Rock GPAA outing this weekend and will post the video when I get back.

Here is the list of what I used;

(1) 1 1/4" Sump Pump Hose....1 Roll was cheaper at $9.95 per 26ft

(2) 1 1/4" Sump Pump Check Valves......Ace Hardware......$7.00 each

(1) 2" X 2ft PVC pipe

(1) 3/4" X 6ft PVC pipe......used 2ft

(1) 3/4" PVC T........for the handle

(2) 3/4" X 1 1/2".....for the handle

(1) 2" X 2" X 1 1/2" X 1 1/2" 4 way PVC joint

(1) 2" x 3" PVC pipe.......for bottom of 4 way joint

(1) 2" Test plug..............for bottom of 4 way joint

(1) 3/4" X 1/8" X 36" aluminum flat bar.....for foot stirrup

(1) 2" cap...........drill out a center hole slightly bigger than 3/4" to let the pump shaft slide through the cap

(1) 1 1/4" PVC collar

(1) 1 1/4" PVC plug

(1) 1 1/4" X 3/4" adapter

(2) 1 1/2" slip collars

(2) 1 1/2" X 1 1/2" PVC pipe

(4) 5/16 X 3/4' bolts

(4) 5/16 nylon lock nuts

(2) 2" X 1/8" O-rings

For the bucket;

(1) 5 gallon bucket, w/lid

(1) 1 1/4" threaded hose collar.....comes with sump pump hose kit

(1) 1 1/4" threaded female collar

Using a 1 1/4" hole saw drill out a hole in the center of the lid. Insert the hose collar and on the inside of the bucket lid screw the threaded female collar on the hose collar/fitting.

I drilled (6) 3/4" holes around the lid so water can get out of the bucket.

I pretty much glued the pipe together with the 4 way and the check valves. I left the cap loose and ONLY hand pushed it down on the pipe so I can be able to remove the handle and piston to lube or change out the o-rings.

I filed groves in the piston collar and test fit little by little until the piston slid just easy enough to work and still seal. Get some silicome spray lubricant, (NOT the oil base kind), and spray the o-rings so the piston and the o-rings slide up and down in the cylinder easily. Be careful about filing too much down or the o-ring won't seal the cylinder. I also drilled a 3/8 hole into one side of the handle/piston shaft so air can escape the cylinder while pulling the handle up. The black band on the handle shaft is not tape. I painted a black band on it so I know when I am pulling the handle up I have the piston up at the top of the cylinder cap so I won't pop the cap off.

I also just inserted the 2" test plug and tightened it down so I can remove it to clean out the pump and check to see if any gold has been lodged in anywhere.

I bent the aluminum flat bar to make a stirrup to put my foot in while I use one hand to pump and the other to use my suction wand.

Attachments

jog

Bronze Member

- Joined

- Nov 28, 2008

- Messages

- 1,364

- Reaction score

- 682

- Golden Thread

- 0

- Location

- Tillamook Oregon

- Detector(s) used

- Whites MXT / GMT

- Primary Interest:

- All Treasure Hunting

TheHarleyMan2

Hey man that looks very PROFESSINAL, very nice. Would like to see the video.

Hey man that looks very PROFESSINAL, very nice. Would like to see the video.

Goodyguy

Gold Member

- Joined

- Mar 10, 2007

- Messages

- 6,489

- Reaction score

- 6,913

- Golden Thread

- 0

- Location

- Arizona

- Detector(s) used

- Whites TM 808, Whites GMT, Tesoro Lobo Super Traq, Fisher Gold Bug 2, Suction Dredges, Trommels, Gold Vacs, High Bankers, Fluid bed Gold Traps, Rock Crushers, Sluices, Dry Washers, Miller Tables, Rp4

- Primary Interest:

- All Treasure Hunting

Harley,

Adding that foot stirrup was sheer genius

Awesome job

GG~

Adding that foot stirrup was sheer genius

Awesome job

GG~

TheHarleyMan2

Bronze Member

- Joined

- Feb 27, 2008

- Messages

- 1,594

- Reaction score

- 465

- Golden Thread

- 0

- Location

- Never Know I May Live Next To You!

- Detector(s) used

- GTI 2500/Bounty Hunter

Minelab Equinox 800

- Primary Interest:

- All Treasure Hunting

Thanks Jog and GG!

I figured after seeing the Gold N Sand model and others ones other people made, you have to use both hands. I figured that by using a stirrup design for 1 foot to hold the pump down while you use one hand to work the pump and the other hand to move the wand, (without ever losing your spot you are sucking sand, water, and maybe some gold), and move along under a boulder, crevis, etc, and just move in one good sweep sucking up everything around while pumping!

I thought about patent and copy right the design but hey anyone can make it so I figured I would just post what I used for it so others can make theirs as well!

I like the design of using the test plug at the bottom so I can remove it and clean out the pipe if I have to. I am going to make another one or to sometime soon and this time instead of glueing in the check valves I am going to use threaded PVC collars for them. I left my suction PVC tude a little long that way I can reach into deeper areas.

I am itching to go out to Longs tomorrow and try it out rather than waiting for the Halliburton outing this weekend, but hey, either way I am excited to try it out along with my new Garrett GTI 2500!!!!!!!!

I figured after seeing the Gold N Sand model and others ones other people made, you have to use both hands. I figured that by using a stirrup design for 1 foot to hold the pump down while you use one hand to work the pump and the other hand to move the wand, (without ever losing your spot you are sucking sand, water, and maybe some gold), and move along under a boulder, crevis, etc, and just move in one good sweep sucking up everything around while pumping!

I thought about patent and copy right the design but hey anyone can make it so I figured I would just post what I used for it so others can make theirs as well!

I like the design of using the test plug at the bottom so I can remove it and clean out the pipe if I have to. I am going to make another one or to sometime soon and this time instead of glueing in the check valves I am going to use threaded PVC collars for them. I left my suction PVC tude a little long that way I can reach into deeper areas.

I am itching to go out to Longs tomorrow and try it out rather than waiting for the Halliburton outing this weekend, but hey, either way I am excited to try it out along with my new Garrett GTI 2500!!!!!!!!

GrayCloud

Bronze Member

Nice looking unit  Not bad for an X-Louisiana Boy.

Not bad for an X-Louisiana Boy.

Don't get too dependant on the 2500 target ID. You will find yourself passing up possible cache finds. Those that get lazy and only want to dig coins are guilty of this. And yes, I am speaking from experience.

Not bad for an X-Louisiana Boy.

Not bad for an X-Louisiana Boy.Don't get too dependant on the 2500 target ID. You will find yourself passing up possible cache finds. Those that get lazy and only want to dig coins are guilty of this. And yes, I am speaking from experience.

Caminochaos

Full Member

- #37

Thread Owner

Very nice HarleyMan! The next one you build are you going to do a step by step on how to build it?

TheHarleyMan2

Bronze Member

- Joined

- Feb 27, 2008

- Messages

- 1,594

- Reaction score

- 465

- Golden Thread

- 0

- Location

- Never Know I May Live Next To You!

- Detector(s) used

- GTI 2500/Bounty Hunter

Minelab Equinox 800

- Primary Interest:

- All Treasure Hunting

Well I had to go out to Longs in Kingsland and try out my detector and suction pump. The pump being 2 ft tall not including the stirrup, it is way to high to bend down with the suction wand and to pump with the other hand. So I am going to cut the tube down to about 16-18 inches.

I did find a gold flake and my detector sounded off on a rock that is compacted sandstone, (schist), and another one that has what looks like silver in it like someone shot it with a shotgun pellets!

Here is the 2 pictures of the rock

I did find a gold flake and my detector sounded off on a rock that is compacted sandstone, (schist), and another one that has what looks like silver in it like someone shot it with a shotgun pellets!

Here is the 2 pictures of the rock

Attachments

Goodyguy

Gold Member

- Joined

- Mar 10, 2007

- Messages

- 6,489

- Reaction score

- 6,913

- Golden Thread

- 0

- Location

- Arizona

- Detector(s) used

- Whites TM 808, Whites GMT, Tesoro Lobo Super Traq, Fisher Gold Bug 2, Suction Dredges, Trommels, Gold Vacs, High Bankers, Fluid bed Gold Traps, Rock Crushers, Sluices, Dry Washers, Miller Tables, Rp4

- Primary Interest:

- All Treasure Hunting

Awesome find Harleyman!

That's Llanite !!!...... Rare... found only one place in the world

A hypabyssal rhyolite porphyry dike (commonly referred to as Llanite) from the Llano Uplift of Central Texas contains phenocrysts of reddish microcline feldspar and blue quartz. The blue quartz phenocrysts are generally euhedral with color zoning from light blue cores to dark blue edges. Quartz phenocrysts retain beta quartz dipyramidal shapes and are up to 5 mm in diameter. The quartz and microcline phenocrysts are enclosed in a microcrystalline matrix of quartz, microcline, plagioclase, biotite, and minor fluorite, magnetite, apatite and zircon.

GG~

That's Llanite !!!...... Rare... found only one place in the world

A hypabyssal rhyolite porphyry dike (commonly referred to as Llanite) from the Llano Uplift of Central Texas contains phenocrysts of reddish microcline feldspar and blue quartz. The blue quartz phenocrysts are generally euhedral with color zoning from light blue cores to dark blue edges. Quartz phenocrysts retain beta quartz dipyramidal shapes and are up to 5 mm in diameter. The quartz and microcline phenocrysts are enclosed in a microcrystalline matrix of quartz, microcline, plagioclase, biotite, and minor fluorite, magnetite, apatite and zircon.

GG~

TheRandyMan

Hero Member

- Joined

- Apr 3, 2010

- Messages

- 576

- Reaction score

- 16

- Golden Thread

- 0

- Location

- Dallas, Texas

- Detector(s) used

- Excalibur II, Minelab Etrac, Ace 250k, Discovery TF-900

- Primary Interest:

- All Treasure Hunting

Nice ID work there GG...the magnetite in that rock is what lit up your detector Harelyman. Wonder what that rock would look like in polished slices?

Similar threads

- Question

- Replies

- 14

- Views

- 813

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)

Latest Discussions

-

-

-

-

-

Welcome to the site! Please post an introduction thread.

- Latest: Sand Swinger

-