johnedoe

Bronze Member

- Joined

- Jan 15, 2012

- Messages

- 1,489

- Reaction score

- 2,242

- Golden Thread

- 0

- Location

- Oregon Coast

- Detector(s) used

- White's V3i, White's MXT, and White's Eagle Spectrum

Cleangold sluice & prospectors pan, EZ-Gold Pan, and custom cleanup sluice.

- Primary Interest:

- Other

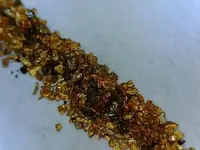

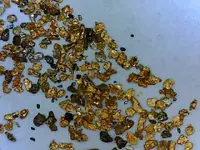

This was developed by Randy Clarkson, an expert in gold recovery designs.

A simple gizmo to help miners snag lost gold..... New gizmo could help placer miners snag lost gold | Yukon News

Also this by Randy Clarkson on fine gold recovery which is somewhat misleading in that this is mostly about commercial ops and 1" minus classification is considered fine....... The Clarkson Study Fine Gold Recovery

Here is a PDF presentation of the process....... http://www.geology.gov.yk.ca/pdf/141114_Nov1014_Grinding_for_Gold_Presentation.pdf ....... Thank you arizau for finding that PDF

Enjoy the learning.

A simple gizmo to help miners snag lost gold..... New gizmo could help placer miners snag lost gold | Yukon News

Also this by Randy Clarkson on fine gold recovery which is somewhat misleading in that this is mostly about commercial ops and 1" minus classification is considered fine....... The Clarkson Study Fine Gold Recovery

Here is a PDF presentation of the process....... http://www.geology.gov.yk.ca/pdf/141114_Nov1014_Grinding_for_Gold_Presentation.pdf ....... Thank you arizau for finding that PDF

Enjoy the learning.

Last edited:

Upvote

0