SchoolOfHardRocks

Sr. Member

Every time I read that report I find more things that just don't play out in the field. Basically by the end your classifying to 8 mesh and using a trowel in the hopes of perfect recovery.

You can for sure feed unclassified with a shovel into a standard box with decent flow and not 'LOSE' the amount of gold inferred.

All the horror stories....stopping and restarting, losing as the h20 stops, clay robbing, scouring. In a regular in stream operation they are so minimal there is no reason to be concerned. Test your tailings....test them as you run ith a tub at the end ...feed a bucket let the water run clear for thirty seconds test your collection material. If there is any gold it is about negative three cents in value.

I get the reason that guys that dig only fine gold desire to catch more of it. A self classifying sluice is a good Idea. If I lived in an area like that I would make a hydrauilic concentrator that had a large screen for throughput 1/4 inch clasifacation and a long narrow sluice that had shallow recovery and a slick plate.

Power sluices are very tuneable. The report above makes it sound like your silly for using one. Again back to the tiny hand scoop!!!! Turbulance and fast h20 speed can increase the chance of loss...but if you can get your feed to stratify moderately and give some length to settle out you are going to have very resonable recovery rates.

There are adjustments to make based on material and h20 availability. Moving volume is still the most important aspect of production.As you read about undercurrents on large operations you discover that most operations abandoned them as they barely added up to 5% additional recovery on large operations. In situations that had runs of hundreds of tons ran and clean ups done maybe monthly. Sometimes bi- monthly.

To me classifacation is important if you have less than ample h20 and if you must clean cobbles. The reason sluices came into use is the fact that they cleaned material as it ran through the troughs and man hours that had been used for screening and moving tailings out of the dig/feed area could be put into digging more material. Only couple sluice tenders are needed to rake and clear cobble.

If it hadn't had such an impact on production it would not have taken over the way placering was done.

If more people watched Doc's video's less people would share this study!!!

sorry Goodyguy

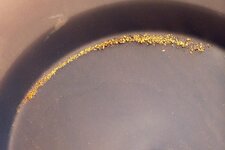

Agreed. Too many prospectors spend too much time & money trying to save every last speck. My thought process is: I don't mind losing a speck or 5 because I will be gaining 10-20 specks during the same time I would have lost. Like you said, if one is in an area full of fines...things might be different. But generally speaking, my theory has worked well for me. You should see the faces of buddies who have gone out with me when I shovel directly into a stream sluice, quick pan material, or squirt excess water out of my snuffer lol. People have even panned my tailings! I'm OK with losing a little to gain more

Last edited: