restless spirit

Full Member

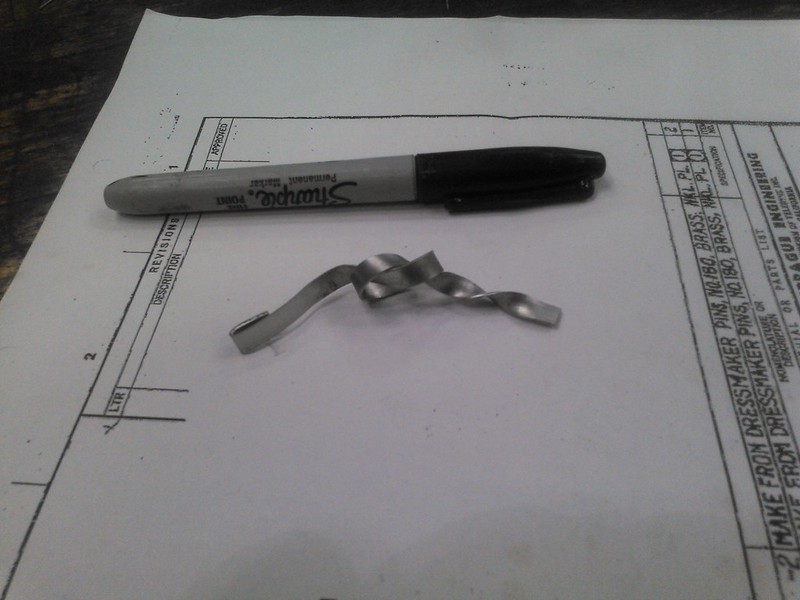

so ive been lookin for a Thomas creek self classifier sluice and havnt had any luck finding one. so I decided to make one.only I wanted to make one that is a little smaller .anyways heres my template made from postar board just to see if measurement are gonna work. so now that it seems easy enough to make I'm just wondering if there is a standard thickness amongst sluice makers? not to heavy but not to flexable. any one have any recomendations