Au dave

Sr. Member

- Aug 5, 2015

- 296

- 593

- Detector(s) used

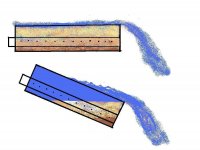

- Home made drop riffle, 'zook' mini prospector, 'zook' sniper

- Primary Interest:

- Other

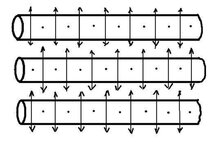

I have read of this interference bar but have not put one in my diy zooks , both of which do catch fine gold... do you think it would be an advantage in my case..No need for a funnel. The pressure of the water hitting the wall will force the water through the tubes. On the underside of the top deck inside the trap you need to mount a bar that goes sideways across the trap. When the gold goes through the Grizzlies it will run into or knock into this bar causing it it lose energy and sink or the disturbance from the water running into the bar will help it sink. The bar does not need to be very large maybe 3/4" at most and mounted close to the Grizzlies.

Sent from my GT-I9305 using Tapatalk