russau

Gold Member

- Joined

- May 29, 2005

- Messages

- 7,796

- Reaction score

- 7,608

- Golden Thread

- 0

- Location

- St. Louis, missouri

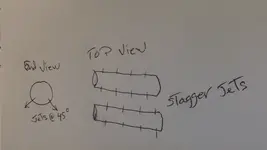

Ive been tinkering/thinking of building a Bazooka style sluice for my 2 inch dredge to try it out in addition to the other sluices ive built for it. THEN I came across (again) GoodGuys fluidbed for the end of the sluice. it brings back memories (15 years ago)of when I built my first fluidbed ( 16x 10 x 6 deep)for my 4 inch dredge (now Bill_Saf dredge) it hung on the end of my sluice. but it would tip the tailend because of the accumulated BS . it worked fine except for the BS build up . Im thinking of building another one for the newer 2 inch that I built. I hope Buddy don't mind if I copy his FB and give it a try. the top half of the sluice will be for the dredged material and the lower section that used the streams water flow to create the fluidizing of material in the FB will be done with a pressureline from my pump. and to adjust the flow/pressure ill put a valve and make a water column gauge to know what my water column is so I can redo the results next time I dredge. what else can I do when needing a set of knees? may as well do this since im stuck at home!