Newbie here - I've got an interesting project going on in TX and thought I might be able to get some advice.

A catastrophic flood in our area trashed our property, and deposited mountains of sand in our lake. We've done all sorts of things to help move it around, one of them being deploying my years of watching every episode of Gold Rush.

The lake in front of our place is roughly a foot deep. My goal is to clear out sand in a channel that is 2-3' deep in order to be able to get a boat in and out. I only need to get a fishing boat in/out, it draws about 18", but a couple extra inches wouldn't hurt. I can either move the sand out of the lake, or spray it off to side/distribute it. In theory I could also blast it to move it.

As a test - I got myself a 3" Tomahawk pump: https://tomahawk-power.com/products/3-gas-water-pump. Sure enough I can move some sand - I've spent a couple full days in the water and I've been able to cut a 2-3' channel about 60' long and 10' wide. The problem is the pump housing is aluminum, and even though it is sand, I still get some gravel in it. I've ruptured the pump housing twice now, and I've been using the strainer on the intake hose.

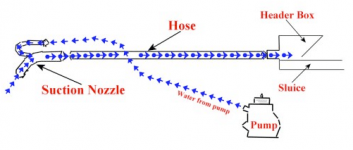

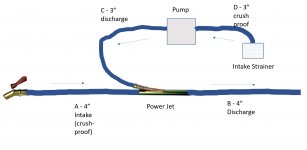

I'd like to move up to something more industrial-strength, preferably that will move more sand. I also wouldn't mind something that floats - I'm currently setting this pump on either the shore, the dock, or a jon boat. Clearly I don't need a sluice box...

Is the answer to get something like a Keene 5" configured with no sluice, but an output hose? Or am I using the right gear - just need something more heavy duty with a cast-iron pump housing? Something like this allows for larger solids: https://www.northerntool.com/shop/tools/product_200585488_200585488

Any thoughts would be appreciated!

A catastrophic flood in our area trashed our property, and deposited mountains of sand in our lake. We've done all sorts of things to help move it around, one of them being deploying my years of watching every episode of Gold Rush.

The lake in front of our place is roughly a foot deep. My goal is to clear out sand in a channel that is 2-3' deep in order to be able to get a boat in and out. I only need to get a fishing boat in/out, it draws about 18", but a couple extra inches wouldn't hurt. I can either move the sand out of the lake, or spray it off to side/distribute it. In theory I could also blast it to move it.

As a test - I got myself a 3" Tomahawk pump: https://tomahawk-power.com/products/3-gas-water-pump. Sure enough I can move some sand - I've spent a couple full days in the water and I've been able to cut a 2-3' channel about 60' long and 10' wide. The problem is the pump housing is aluminum, and even though it is sand, I still get some gravel in it. I've ruptured the pump housing twice now, and I've been using the strainer on the intake hose.

I'd like to move up to something more industrial-strength, preferably that will move more sand. I also wouldn't mind something that floats - I'm currently setting this pump on either the shore, the dock, or a jon boat. Clearly I don't need a sluice box...

Is the answer to get something like a Keene 5" configured with no sluice, but an output hose? Or am I using the right gear - just need something more heavy duty with a cast-iron pump housing? Something like this allows for larger solids: https://www.northerntool.com/shop/tools/product_200585488_200585488

Any thoughts would be appreciated!