omnicron

Bronze Member

Figured I would share my misfortune again with you guys...

I went up to sample/dredge a new spot up creek from where I pulled 5 ounces last year. It started out with this:

Caused by this:

I'm lucky that I had a spare/jack/tire iron.

But my luck ran out there...

Once again I had issues with my new Keene foot valve. I pump and pump and it leaks back out the rubber flap. In 3 days I guess I lost almost 3 hours of dredging time trying to prime the engine, taking the valve apart looking for the cause... I have decided to add a bilge pump priming feature to solve this problem. I'm going to plumb it in through the hose port. Hope it works!

So back to the spot I tested...I move roughly 8'x20'x36" of overburden to get to this clayish type of material. It's greyish blue, has small pea sized gravel and what looks to be pyrite but very little gold I punch a hole down about 3' of this clay type of material bed rock only to find the bedrock is smooth, not worth the time. Kind of surprising considering this creek was bucket line dredged in the late 1800's or early 1900's. Total for that day... point eight grams...doesn't even cover the gas in the engines.

So I pack up everything the next day and go back to my old spot. I stopped dredging there last year and all there is left is "crumbs" as I call it.I decided to fall back to were I started last year, dredging where my tailing pile was. So once again I cleared a 8'x20'x36" of overburden to the hardpack. I didn't touch the hardpack that day.

Gold for Saturday... point five grams.

Sunday I start in the hardpack following what should be the path of gold (inside bend) In three hours I cleared a 4'x5' section of hardpack with cracking/crevicing the bedrock. I did fast clean up of the mats... point four grams...Not good

I jump to the other side of creek (out side of the bend) and cleared another 4'x5' section of hard pack with cracking/crevicing the bedrock in 3 hours. I finished running my cons today from my last run... two point seven grams.

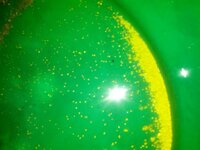

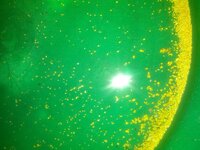

I want to add this for people who are on the fence about gold hog mats...

They work and they work good. Look at the fine gold I'm catching. There's no question about how well they recover. I'll add that I don't have a way to catch 100% of my tailing working by myself so I just checked my tailing with a gold pan from different spots. I didn't find anything but that doesn't mean I'm not losing gold, just means I didn't find any and the material I was running wasn't very rich.

See how fine this gold is? Lovin the River Hog.

I went up to sample/dredge a new spot up creek from where I pulled 5 ounces last year. It started out with this:

Caused by this:

I'm lucky that I had a spare/jack/tire iron.

But my luck ran out there...

Once again I had issues with my new Keene foot valve. I pump and pump and it leaks back out the rubber flap. In 3 days I guess I lost almost 3 hours of dredging time trying to prime the engine, taking the valve apart looking for the cause... I have decided to add a bilge pump priming feature to solve this problem. I'm going to plumb it in through the hose port. Hope it works!

So back to the spot I tested...I move roughly 8'x20'x36" of overburden to get to this clayish type of material. It's greyish blue, has small pea sized gravel and what looks to be pyrite but very little gold I punch a hole down about 3' of this clay type of material bed rock only to find the bedrock is smooth, not worth the time. Kind of surprising considering this creek was bucket line dredged in the late 1800's or early 1900's. Total for that day... point eight grams...doesn't even cover the gas in the engines.

So I pack up everything the next day and go back to my old spot. I stopped dredging there last year and all there is left is "crumbs" as I call it.I decided to fall back to were I started last year, dredging where my tailing pile was. So once again I cleared a 8'x20'x36" of overburden to the hardpack. I didn't touch the hardpack that day.

Gold for Saturday... point five grams.

Sunday I start in the hardpack following what should be the path of gold (inside bend) In three hours I cleared a 4'x5' section of hardpack with cracking/crevicing the bedrock. I did fast clean up of the mats... point four grams...Not good

I jump to the other side of creek (out side of the bend) and cleared another 4'x5' section of hard pack with cracking/crevicing the bedrock in 3 hours. I finished running my cons today from my last run... two point seven grams.

I want to add this for people who are on the fence about gold hog mats...

They work and they work good. Look at the fine gold I'm catching. There's no question about how well they recover. I'll add that I don't have a way to catch 100% of my tailing working by myself so I just checked my tailing with a gold pan from different spots. I didn't find anything but that doesn't mean I'm not losing gold, just means I didn't find any and the material I was running wasn't very rich.

See how fine this gold is? Lovin the River Hog.

Last edited:

?? I've had dozens hit my tps and zero,zilch,natha nuttn'.....to thine own self be true-John

?? I've had dozens hit my tps and zero,zilch,natha nuttn'.....to thine own self be true-John