AzViper

Bronze Member

- Joined

- Sep 30, 2012

- Messages

- 2,038

- Reaction score

- 2,251

- Golden Thread

- 0

- Detector(s) used

- Fisher Gold Bug Pro, Nokta FORS Gold, Garrett ATX, Sun Ray Gold Pro Headphones, Royal Pick, Etc.

- Primary Interest:

- Prospecting

Jeff95531 contacted me in regards with some questions in regards to the Miller Table and some links on eBay. My reply was don’t buy and let me build you a rubber mat Miller Table. I told Jeff that the table does not need to be very wide or very long. With that said I will build Jeff a copy of my Miller Table but on a slightly smaller scale. Jeff will be in charge of gathering a tub and a means of securing the Miller Table where he can adjust the angle and side to side to get the water flowing evenly. (I suggest coping my PVC frame on a smaller scale)

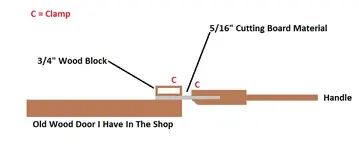

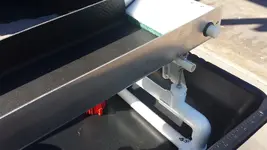

The Miller Table will be 7” wide and 24” long. Does not need to be any larger and will have a vial mounted into the upper end making collecting the gold a breeze. The parts that you see below are what are needed and some ½” nylon plate to cap the end of the table.

Rubber Grommets, 1/2" Pipe, Vial, Water Valve, 1/2' End Cap, Brass Hose Barb, Rubber Mat, Folded Aluminum Box, Attwood 500 GPH Pump, Scotch Brite Pad, and #6 x 3/4” Stainless Steel Screws. Not shown is the nylon plate for the end cap and water diffuser.

For anyone that has not seen the finished Rubber Mat Miller Table here is a link to my larger table and video's of the table working. Rubber Mat Miller Table

The Miller Table will be 7” wide and 24” long. Does not need to be any larger and will have a vial mounted into the upper end making collecting the gold a breeze. The parts that you see below are what are needed and some ½” nylon plate to cap the end of the table.

Rubber Grommets, 1/2" Pipe, Vial, Water Valve, 1/2' End Cap, Brass Hose Barb, Rubber Mat, Folded Aluminum Box, Attwood 500 GPH Pump, Scotch Brite Pad, and #6 x 3/4” Stainless Steel Screws. Not shown is the nylon plate for the end cap and water diffuser.

For anyone that has not seen the finished Rubber Mat Miller Table here is a link to my larger table and video's of the table working. Rubber Mat Miller Table

Amazon Forum Fav 👍

Last edited:

Upvote

0

now that's a boo boo a band aid aint gonna fix

now that's a boo boo a band aid aint gonna fix ooooooh thats not right.

ooooooh thats not right.