johngfoster

Jr. Member

- Feb 7, 2016

- 54

- 66

- Detector(s) used

- 30" Prospector BGT,

Garret pans (10", 14", SuperSluice),

Home-built Gold Hog-ish Highbanker a la Raptor

- Primary Interest:

- All Treasure Hunting

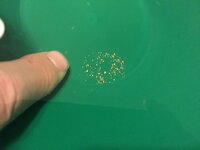

Any of you guys build your own highbanker? I've finally gotten around to putting one together. Made from 1/16" (0.063") 6061 Aluminum. Sluice is 9" wide, 6" high, and 48" long. Fitted for a 1 1/2" hose. Still have to finish cutting the Gold Hog matting and install the legs.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk