therobertsmith

Full Member

- Thread starter

- #21

Some is. I have a 20 classifier now until friday when the other's come in. Even when I run the 20s it still clogs up. It seems the sediment sticks back together in the box. I am wondering if I should stir the bucket first to break up the mix. It is hard as concrete if it sits for 2 days.

I just spend a hour in lowes trying to find a bigger fitting for a larger pump. Seems everyone wants to know what its for and then they all say "oh I see that show on Discovery"

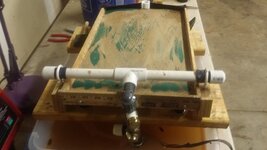

Shake my head and walk away. But here is my upgrade.

I just spend a hour in lowes trying to find a bigger fitting for a larger pump. Seems everyone wants to know what its for and then they all say "oh I see that show on Discovery"

Shake my head and walk away. But here is my upgrade.