- #21

Thread Owner

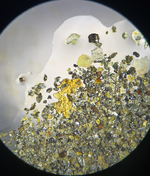

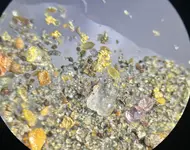

Typo. Meant grade not gray.Some equipment that is not worn out is a plus to get to that level. The gray stuff could be a better grade in the outer parts next to the contact zone?

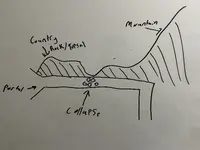

Why did it cave in?

Did the other people run out of better materials?

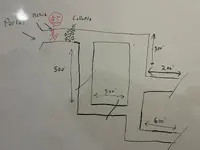

Bad ground conditions. There isn't much country rock above the adit going back for a ways. Which is probably why I'm screwed on clearing the collapse and better off starting a new one further back.

I don't know what you mean better materials. They were mining something before the collapse, so there has to be something worthwhile. Apparently he wanted to get back to it for years but couldn't find anyone young and motivated enough to help.