jcazgoldchaser

Hero Member

- Joined

- May 8, 2012

- Messages

- 899

- Reaction score

- 515

- Golden Thread

- 0

- Primary Interest:

- All Treasure Hunting

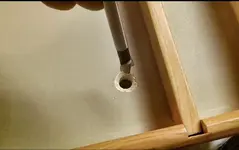

Easy Liner Ultra Fresh was:Found it! Miller table surface

Walking through home depot on a clearance run I noticed an upside down holiday mat. What caught my eye was the rubber backing was little circle dimples like a gulf ball. I can't find Attila's post offhand, but here's his Utube video

I'll get the numbers off the mat in case anyone else state side is interested. I did try to peel the front off and it seems to come away pretty easily. Course, 5 inches in may be completely different.

Walking through home depot on a clearance run I noticed an upside down holiday mat. What caught my eye was the rubber backing was little circle dimples like a gulf ball. I can't find Attila's post offhand, but here's his Utube video

I'll get the numbers off the mat in case anyone else state side is interested. I did try to peel the front off and it seems to come away pretty easily. Course, 5 inches in may be completely different.

Amazon Forum Fav 👍

Last edited:

Upvote

0