Hephaestus

Greenie

- Jul 16, 2018

- 19

- 11

- Primary Interest:

- All Treasure Hunting

Hi everyone,

Working on a fluidized bed highbanker design. I've spent inordinate amounts of time reading just about every thread here...

Wondering if you guys have run across research on extraction using fluidized beds?

Curious if there's data on feed rates / volumes of water, better fluid distribution models than the ones we typically see DIY'd. Pan shape etc.

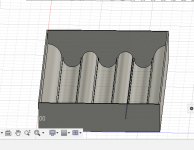

I started this simple, and after realizing the cost to 3d print at the library is cheaper than the galvanized tin & plumbing bits I intended to use - I'm having new thoughts about the fluid bed. Incorporating the pipes into the design, drawing the nozzles in at specific angles instead of halfhazardly hand drilled...

But I figure there must be research my Google-fu just isn't finding on the topic. I figured I'd ask here since I know some of you probably have some long saved links on the topic that I'm clearly not using the right terms to find...

Thanks in advance!

Working on a fluidized bed highbanker design. I've spent inordinate amounts of time reading just about every thread here...

Wondering if you guys have run across research on extraction using fluidized beds?

Curious if there's data on feed rates / volumes of water, better fluid distribution models than the ones we typically see DIY'd. Pan shape etc.

I started this simple, and after realizing the cost to 3d print at the library is cheaper than the galvanized tin & plumbing bits I intended to use - I'm having new thoughts about the fluid bed. Incorporating the pipes into the design, drawing the nozzles in at specific angles instead of halfhazardly hand drilled...

But I figure there must be research my Google-fu just isn't finding on the topic. I figured I'd ask here since I know some of you probably have some long saved links on the topic that I'm clearly not using the right terms to find...

Thanks in advance!