Bandmenter

Jr. Member

- Oct 28, 2016

- 55

- 45

- Detector(s) used

- Whites GMT, Fisher F75 SE

- Primary Interest:

- All Treasure Hunting

Well, winter is closing in on the outside activities so what to do 'til spring? Reviewing my options I could sit around watching TV or YouTube prospecting videos, work on the wife's honey do lists or I could build something. I choose the later.

So I wanted to build a light weight clean up sluice that could also be used to run serious amounts of material. I have a source of flood sands that I should be able to access through the winter and processing in the warmth of the workshop.

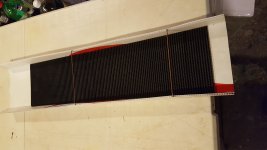

I got a hold of Kevin Bell of Snake River Products and ordered some Vortex matting, grabbed an old political yard sign then started building. Please see photo log.

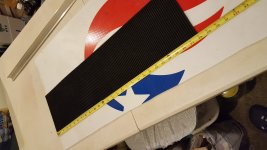

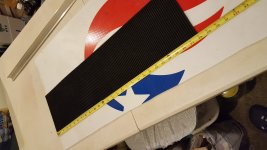

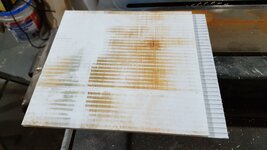

Layout and measure materials determining scope of what you can build.

Measure and cut the material. When cutting the side of the sluice you want to just score the sign material and fold the sides up.

I will continue this post later.

So I wanted to build a light weight clean up sluice that could also be used to run serious amounts of material. I have a source of flood sands that I should be able to access through the winter and processing in the warmth of the workshop.

I got a hold of Kevin Bell of Snake River Products and ordered some Vortex matting, grabbed an old political yard sign then started building. Please see photo log.

Layout and measure materials determining scope of what you can build.

Measure and cut the material. When cutting the side of the sluice you want to just score the sign material and fold the sides up.

I will continue this post later.

Last edited:

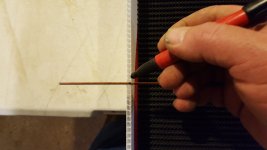

You might have to experiment on the "slot in the T". I had to go with drilled holes to get a good even flow.

You might have to experiment on the "slot in the T". I had to go with drilled holes to get a good even flow.