BillA

Bronze Member

This thread is about building a suction pump for crevasse cleaning, and then rebuilding it, and then yet again, and . . . . where does it stop?

It is a DIY thread including particularly design or fabrication novelties, hands-on experience works.

(mods, if in wrong place - move 'er)

Many names for these, manual gravel pump is descriptive, gold sucker is common, and my favorite is chupadora (sucker in Spanish).

An old-timer seeing one called it a chupadora, used for removing gold from full riffles without shutting down the sluice.

As I am in a remote, but gold-bearing, area my only option is to build from that which is at hand; PVC DWV here we come.

I took a gander at the 'net to find out what everyone else knew/offered and of course made a list:

- ovaled end of suction tube with pin (maximize size while limiting blockage)

- changeable suction nozzle diameters/lengths ?

- retention resiviour for the work product that is easily emptied

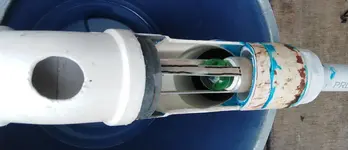

so I made one (shown is the last of the straight pumps, I use clear tubing when I wish to see what's happening)

A bit of use and it was very clear that the pump body should be offset from the suction head for comfort.

At the same time that a 45 ell was added, following the maxim that more is better, the 1 1/2" suction tube was exchanged for 2".

And in 2" exploring resiviour configurations:

So what was learned from these prototypes ?

1) the suction tube diameter and length is limited by the pump displacement (no free lunch)

2) having to discharge the sucked-up water through the same tube is disruptive as hell. No stroke is truly completed, good stuff dribbles out the tube end; terrible efficiency

3) top of resiviour should be below bottom of branch connection and resiviour needs to be translucent

Obviously a second discharge/jet tube needs to be added and the flow controlled such that the suction tube sucks and the pressure tube jets. Enter check valves, one suction and one pressure. Note that the suction tube ck valve must freely pass everything one thinks to retain, while the pressure ck valve . . . . .

comments from the peanut gallery are solicited

Phase Two will be/is the construction of a 2-tube pressure jet/gold sucker

(already done, but I want to see how others address the suction with gravel ck valve)

It is a DIY thread including particularly design or fabrication novelties, hands-on experience works.

(mods, if in wrong place - move 'er)

Many names for these, manual gravel pump is descriptive, gold sucker is common, and my favorite is chupadora (sucker in Spanish).

An old-timer seeing one called it a chupadora, used for removing gold from full riffles without shutting down the sluice.

As I am in a remote, but gold-bearing, area my only option is to build from that which is at hand; PVC DWV here we come.

I took a gander at the 'net to find out what everyone else knew/offered and of course made a list:

- ovaled end of suction tube with pin (maximize size while limiting blockage)

- changeable suction nozzle diameters/lengths ?

- retention resiviour for the work product that is easily emptied

so I made one (shown is the last of the straight pumps, I use clear tubing when I wish to see what's happening)

A bit of use and it was very clear that the pump body should be offset from the suction head for comfort.

At the same time that a 45 ell was added, following the maxim that more is better, the 1 1/2" suction tube was exchanged for 2".

And in 2" exploring resiviour configurations:

So what was learned from these prototypes ?

1) the suction tube diameter and length is limited by the pump displacement (no free lunch)

2) having to discharge the sucked-up water through the same tube is disruptive as hell. No stroke is truly completed, good stuff dribbles out the tube end; terrible efficiency

3) top of resiviour should be below bottom of branch connection and resiviour needs to be translucent

Obviously a second discharge/jet tube needs to be added and the flow controlled such that the suction tube sucks and the pressure tube jets. Enter check valves, one suction and one pressure. Note that the suction tube ck valve must freely pass everything one thinks to retain, while the pressure ck valve . . . . .

comments from the peanut gallery are solicited

Phase Two will be/is the construction of a 2-tube pressure jet/gold sucker

(already done, but I want to see how others address the suction with gravel ck valve)

Amazon Forum Fav 👍

Upvote

0

. If you can suck it up and squirt it right back into a tub or sluice you do not have to take it apart and empty it; and it is really an easy efficient method of cleaning out crevices, pockets and cracks. Granted you can't lallygag in between the suck and shoot but I would contend I can get far more done in less time and clean out a crevice faster than any other hand method. 40 years of doing it has proven it produces the desired outcome. Simple works!

. If you can suck it up and squirt it right back into a tub or sluice you do not have to take it apart and empty it; and it is really an easy efficient method of cleaning out crevices, pockets and cracks. Granted you can't lallygag in between the suck and shoot but I would contend I can get far more done in less time and clean out a crevice faster than any other hand method. 40 years of doing it has proven it produces the desired outcome. Simple works!