nomad 11

Bronze Member

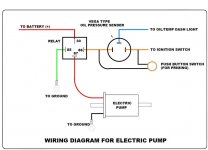

i know this has nuthing to do with metal detecting. but so what right ? its still tech talk. and its puzzling so i need to know. the motor quit. so what id like to know is ? can i check the resistance of the two terminals to possibly determine what went wrong internally ? brushes wore out ? which is the most likely ? so if the brushes wore down to nuthing i should get 0 resistance ? is that right ? or it seized ? also just want to say this is a fuel pump motor about 7 inches long and if it

lasted almost 27 years in my old van then it was a good run huh

lasted almost 27 years in my old van then it was a good run huh

lasted almost 27 years in my old van then it was a good run huh

lasted almost 27 years in my old van then it was a good run huh