Goodyguy

Gold Member

- Mar 10, 2007

- 6,489

- 6,900

- Detector(s) used

- Whites TM 808, Whites GMT, Tesoro Lobo Super Traq, Fisher Gold Bug 2, Suction Dredges, Trommels, Gold Vacs, High Bankers, Fluid bed Gold Traps, Rock Crushers, Sluices, Dry Washers, Miller Tables, Rp4

- Primary Interest:

- All Treasure Hunting

Decided to end the noise from my 2 cycle blower motor and convert my drywasher over to the pleasant sound of a puffer.

While I was thinking about the conversion I wanted to try a new way of operating the bellows that would eliminate the use of the two pulleys and belt with associated linkage.

I have always been fascinated with stamp mills and had the idea that I could operate the bellows by using a cam just like the cam that would raise the stamp rod and then let it drop onto the ore.

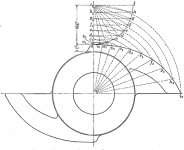

Here is the diagram of the improved version of stamp mill cam that I used for my design.

The cam I made was from wood and I used double sided tape to attach a thin strip of Teflon onto the bottom of the bellows to prevent friction.

Next I wanted a way to regulate the rpm of the cam so I ordered a 12V motor speed controller. $12.06 e-bay

The motor I chose is a two speed windshield washer motor for 1987-1995 Jeep. $28.78 e-bay

Because of the built in gear ratio I am able to go direct drive.

For the Battery I chose a small AGM 12v. 22 amp hour deep cycle. $42.99 e-bay

Here is a photo of the drywasher before the conversion.

Here it is after the conversion..........

Bellows closed .............................Bellows open

The cam has a 6" lift.

I wish I had it on video because the sound is so cool when the bellows drops off the cam and of course the thump when the bellows hits bottom helps send the gold to the bottom of the dirt. I used a length of cord inside the air chamber attached to the floor of the bellows to limit the drop and eliminate strain on the canvas.

The amount of action on the sluice was a bit surprising. The cam and the resulting thump created more movement in the sluice than I had anticipated which was an unexpected plus. I really have to get this thing on video as soon as I can get back out to the claims.

Go for the gold

GG~

While I was thinking about the conversion I wanted to try a new way of operating the bellows that would eliminate the use of the two pulleys and belt with associated linkage.

I have always been fascinated with stamp mills and had the idea that I could operate the bellows by using a cam just like the cam that would raise the stamp rod and then let it drop onto the ore.

Here is the diagram of the improved version of stamp mill cam that I used for my design.

The cam I made was from wood and I used double sided tape to attach a thin strip of Teflon onto the bottom of the bellows to prevent friction.

Next I wanted a way to regulate the rpm of the cam so I ordered a 12V motor speed controller. $12.06 e-bay

The motor I chose is a two speed windshield washer motor for 1987-1995 Jeep. $28.78 e-bay

Because of the built in gear ratio I am able to go direct drive.

For the Battery I chose a small AGM 12v. 22 amp hour deep cycle. $42.99 e-bay

Here is a photo of the drywasher before the conversion.

Here it is after the conversion..........

Bellows closed .............................Bellows open

The cam has a 6" lift.

I wish I had it on video because the sound is so cool when the bellows drops off the cam and of course the thump when the bellows hits bottom helps send the gold to the bottom of the dirt. I used a length of cord inside the air chamber attached to the floor of the bellows to limit the drop and eliminate strain on the canvas.

The amount of action on the sluice was a bit surprising. The cam and the resulting thump created more movement in the sluice than I had anticipated which was an unexpected plus. I really have to get this thing on video as soon as I can get back out to the claims.

Go for the gold

GG~

Amazon Forum Fav 👍

Last edited:

?

?