rosej3570

Jr. Member

- Joined

- May 26, 2016

- Messages

- 41

- Reaction score

- 68

- Golden Thread

- 0

- Location

- Le Claire, IA

- Primary Interest:

- All Treasure Hunting

- #21

Thread Owner

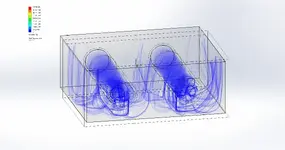

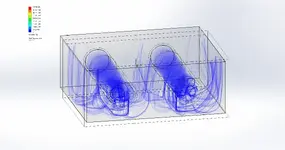

I got a CFD analysis started on the Bazooka-ish Gold Trap. I did 3/32" holes, spaced 1/4" apart, one set down, the next at 45 degrees to the sides, then down again. I ran a lot of simulations and only had a couple vortex's begin. I will run more analysis when I have time. I also have a video, but I have to figure out how to upload it. I wonder if putting in a wedge on the bottom of the bed may help drive vortex's to catch finer gold. I will try it sometime and see.

Last edited: