rosej3570

Jr. Member

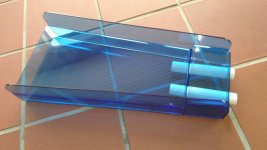

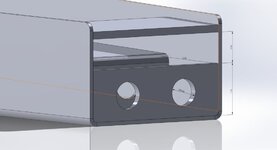

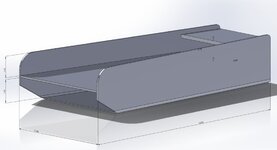

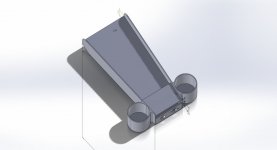

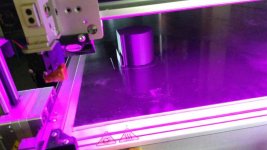

So I just made this. Designed it and created the bend profiles. I want to run some flow analysis simulation on it, but for now, this is what I have. Yes there is tweaking and finishing to be done, but I think it is a good start.

Any thoughts? This is acrylic, but can be done in metal or ABS too.

Sent from my Moto G Play using Tapatalk

Any thoughts? This is acrylic, but can be done in metal or ABS too.

Sent from my Moto G Play using Tapatalk