I hear you there. We're driving drift towards a good 6' core intercept but it's fairly slow going. Lately we've been fighting with dewatering; lines and Victualic couplings are giving us fits. We're getting at it and have the fixed plant recommissioned. It's still a bit before we'll be fully settled into a routine.

View attachment 2074906

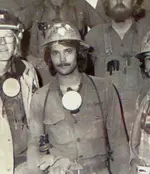

This is after the first blast - had some issues with questionable boosters misfiring which caused the round to partially boot. I took this photo after mucking 90% of the pile, and left a few yards as a platform to drill the upper holes from.

View attachment 2074907

I also picked this little thing up at an auction, it's been phenomenally useful for nipping and utility work. I'll never nip supplies with an LHD again if I can help it!

- digging fast at this point, and preparing to make sure equipment is covered for the deluge about to come!