- Thread starter

- #21

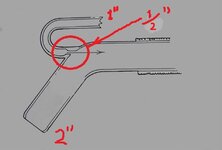

First of all it would help to have a photo of your equipment so we could see exactly what you are working with.

Second a 2" dredge is not going to move an abundance of material. (at max approx 1/2 yard per hour)

There are always ways to increase your suction power by fine tuning the venturi, adding more horsepower, going to a high pressure pump vs a low pressure pump, shortening the hose, reducing the amount of head lift, etc.

If you can place your hand up against the nozzle at the end of the hose and the suction holds it there without the weight of the hose pulling it loose while you're under water, then that's about the most you can expect with the pump you have.

GG~

Yeah let me grab some pictures of what im working with and post them. I feel like im getting confused...lol

Lots of talks about venture.......and things im not familiar with.