Doitlaynstyle

Hero Member

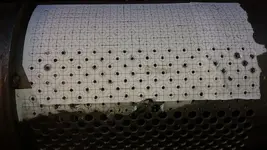

So I have started gathering supplies to begin my trommel build. I'll post a link to AZ's thread which is my inspiration for this build but I'm also planning a different style. I'll be using easily obtainable parts so that rebuilding in the event of failure is possible without fabricating new parts. I'm thinking that at eight foot long I'm going to just turn this thing into a small trailer or build it on a small trailer so that I can also haul the extra gear and make the weekend trips a little more do-able. I will be using one of the two roto-tillers for the gear reduction and I am contemplating using a tubed rubber tire as a drive wheel instead of running a full gear ring on the beast. I will probably still use roller blade wheels for the cylinder rotation but I am probably going to use four on bottom and four on top to lock the cylinder into place so the tire doesn't knock the cylinder up off the bearing wheels.

I'm also hoping that I can get my hands on a claim soon and I'll also be using my father's back-hoe to stockpile dirt, move tailing piles, and create a reclamation pond. Anyway this is the start of a long slow winter because money is tight. We just bought a new house and I'm scrimping more than usual. I'm hoping to build a new 12" sluice box but I might just have to extend my current 10" box. Like AZ I'm hoping to use gold hog mating but that's only if I can afford it. Most likely I'll run my rifles and miners moss first followed by another 3' of box with the gold hog mat I currently have. So enough of this for now. I'll add photos here and link AZ's thread.

http://www.treasurenet.com/forums/gold-prospecting/364420-12-inch-trommel-build.html

I'm also hoping that I can get my hands on a claim soon and I'll also be using my father's back-hoe to stockpile dirt, move tailing piles, and create a reclamation pond. Anyway this is the start of a long slow winter because money is tight. We just bought a new house and I'm scrimping more than usual. I'm hoping to build a new 12" sluice box but I might just have to extend my current 10" box. Like AZ I'm hoping to use gold hog mating but that's only if I can afford it. Most likely I'll run my rifles and miners moss first followed by another 3' of box with the gold hog mat I currently have. So enough of this for now. I'll add photos here and link AZ's thread.

http://www.treasurenet.com/forums/gold-prospecting/364420-12-inch-trommel-build.html

Last edited:

Upvote

0